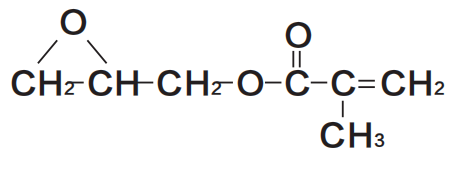

SINOMER® GMA – Glycidyl methacrylate

Cas No.:106-91-2

Molecular Formula: C7H10O3

Molecular Weight:142.15

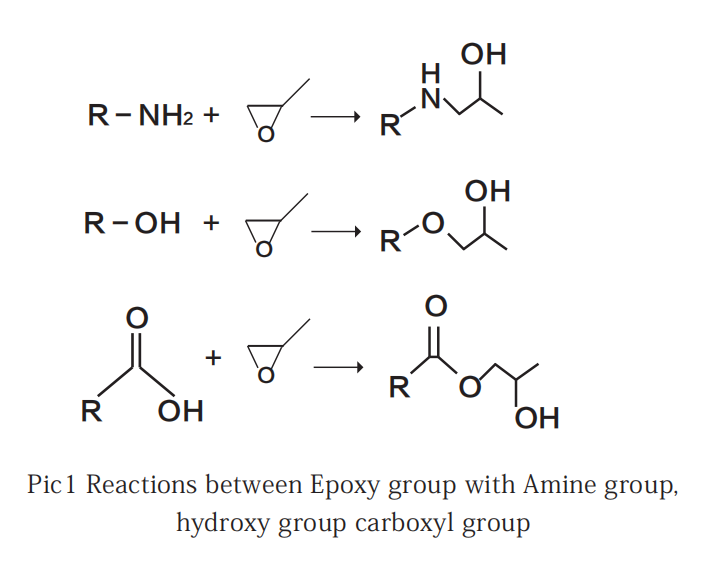

SINOMER® GMA is a monomer contains acrylate’s “C=C”bond and Epoxy Group. With the high reactivity of “C=C”, it can be autopolymerizated, or polymerizated with many other monomers;with Epoxy group, it can take reaction with hydroxy-group, amino-group, carboxyl-group or anhydrides, in order to have more functional groups enter into products for more functions.

SINOMER® GMA was widely used in Organic Synthesis, polymer synthesis, polymer modification, composite materials, UV polymerizations, coatings,Adhensives,Leathers,Chemical Fibers,paper making,dying etc.

At normal temperature,SINOMER®GMA is colorless transparent low viscosityliquid,soluble in common organic solutions, insoluble in water.Asepichlorohydrin takes part in the process,SINOMER®GMA contains a little ofECH .

With Typical flavor of acrylate monomers , SINOMER® GMA is irritative toskin and eye if touched . SINOMER® GMA is combustible both in liquidand gas state. SINOMER® GMA may autopolymerization reaction when thetemperature is high ,inhibitor is necessary to be added .

Application of SINOMER® GMA in Powder Coatings:

Acrylate powder coatings is wide class of powder coatings, according different curing agents ,they are devidedinto:Hydroxyl acrylate resin, Carboxyl acrylate resin, Glycidyl acrylate resin, Acylamino acrylate resin.GMA resinis most widely used ,to be filmed by curing agents such as polyhydroxyl acid,polyanime, ployols.polyhydroxy resin,hydroxyl polyester resin.

The acrylate powder coatings, which using MMA,GMA,BA,Styrene as monomers in polymerization reaction of GMAresin, using 1,10-Decanedicarboxylic acid(DDDA) as curing agant , exhibits good performance.Benzoyl peroxide(BPO) and Azo diisobutyronitrile(AIBN) or its mixture is used as initiator in the synthesis of process.

The effect of GMA dosage on film performance is very large. Lower the dosage, lower the crosslinking degree of theresin, and fewer the curing interconnection points, so that the crosslinking density of the coating is not enough, andthe film resistance is poor.

Application of SINOMER® GMA in Polymer Modification:

With the bond “C=C”,GMA is grafted onto polymers, the epoxy group can take reaction with many other functiongroups to synthesis functional polymers.

The GMA can be grafted by solution-grafting.melt-grafting, solid state grafting,irradiation grafting, etc., also canbe used to form functional copolymer with ethylene and acrylate.These functionalized polymers can be used astoughening agents to toughen engineering plastics or as a compatibilizer to improve the compatibility of blends.

The commonly used initiator for GMA grafting polyolefine modification,including Diisopropyl benzene(DCP),Benzoyl peroxide (BPO).Acrylamide(AM),2,5-2tert-butyl peroxy-2,5-dimethyl-3-hexyne (LPO),1,3-Bis(tert-butyldioxyisopropyl)benzene(BIPB) etc.AM can reduce the Degradation of polypropylene obviously.

Polyolefin grafted GMA can result in the change of polyolefin structure, which can cause the surface performance,rheological energy, thermal performance and mechanical properties of polyolefin. GMA grafting modified polyolefinenhances the polarity of the molecular chain and increases the surface polarity. Therefore, the surface contactangle decreases with the increase of graft rate. Because of the modification of GMA to polymer structure, it can alsoaffect its crystallization performance and mechanical properties.

Application of SINOMER® GMA in Resin Copolymerization:

Ternary copolymer of GMA and styrene, acrylonitrile, can be used for the expansion chain of PA, PC,PBT and PET,for delustering agent of PC/ABS,PA/ABS,PBT/ABS, for compatilizer of ABS/PBT,ABS/PET,PC/ABS.

Application of SINOMER® GMA in UV Curable Resin Synthesis:

Through a variety of synthetic routes,GMA can be used for UV resin synthesis.

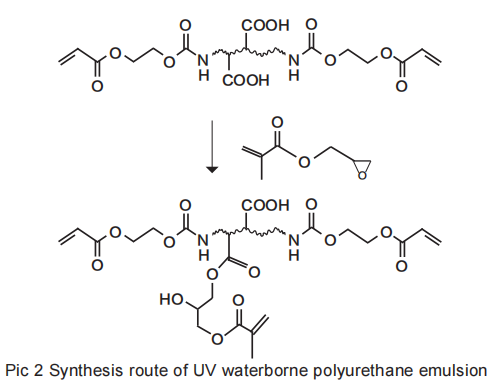

One approach is, by radical polymerization and condensation polymerization to get side chain containing carboxylor amino polymers, and then reacts with GMA and those functional group, the photoreceptors are introduced to getuv-curable resin. In the first stage of copolymerization, different comonomers can be used to obtain polymers withdifferent performance.

Another approach is,GMA and other monomers for copolymerization, to get epoxy group in side chain ofcopolymer, then the epoxy group react with acrylic acid or methyl acrylic acid, so that to get UV curing resins.

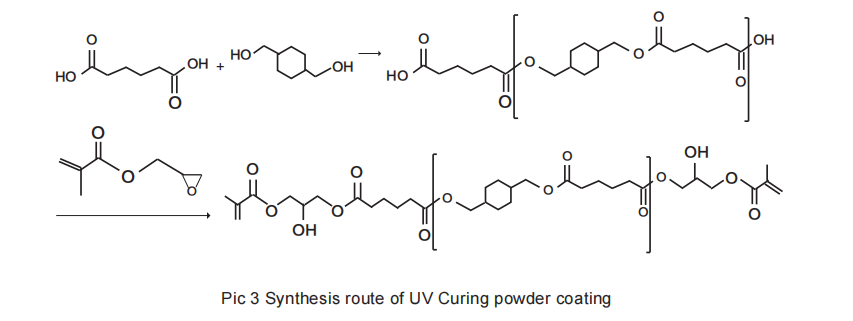

Application of SINOMER® GMA in UV Curing powder coating:

UV curing powder coating is a new technology combining UV curing technology with traditional powder coatingtechnology, it combines the advantages of UV curing and powder coating, and is widely used in the coating ofmedium density fiberboard (MDF) and metal materials.

To synthesize carboxyl-type polyesters firstly, then GMA react with carboxyl group to produce UV curing powdercoatings with photosensitive groups.

Application of SINOMER® GMA in Macroporous Polymers:

GMA as monomer, Divinyl Benzene (DVB) andlor 1,3,5-Tri-2-propeny-1,3,5-riazine-2,4,6(1H,3H,5H)-trione(TAIC)as crosslinking agent, using Toluene and n-Heptane as porogenic agent, to produce macroporous copolymer bysuspension polymerization.

Due to the active epoxy group, macroporous polymer is easy to be chemically modified, so as to prepare

various adsorbents. For example, Solid loaded polymyxin for the treatment of hyperlipemia, Ornithine for the treatment ofsystemic lupus erythematosus. Macroporous polymers can also perform functional reactions with mannitol to obtainpolyhydroxy absorbent.

Besides the application as above, GMA can be used in Adhensive, UV pressure-sensitive adhesive, Auto Coatings,Waterborne coatings, Inks,Resins,Antistatic agent, Polyvinyl fluoride, Non-woven fabrics etc.

With the C=C bond and epoxy group,GMA is widely used in many fields.

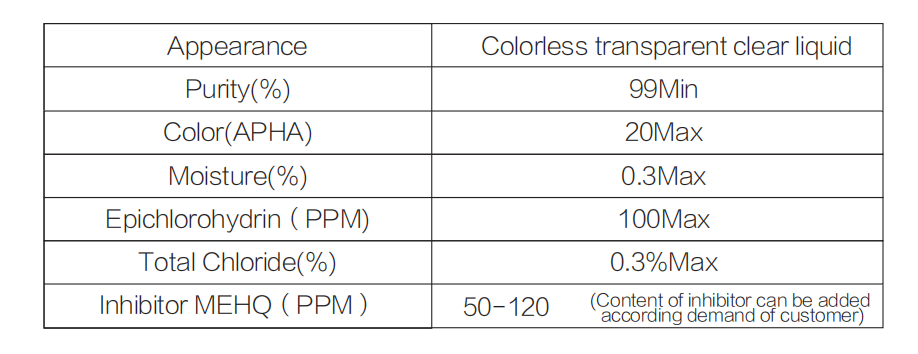

Specification:

Sinocure Chemical Group -Shandong factory now has a 6000 tons/year Glycidyl methacrylate production line, and have been covered by EU REACH,For any further needs, please contact us via email info@sinocurechem.com.