Ethylene is one of the largest chemical products in the world.

A compound composed of two carbon atoms and four hydrogen atoms. Two carbon atoms are connected by a double bond. Ethylene exists in certain tissues and organs of plants. It is converted from methionine under conditions of sufficient oxygen supply. It is also the basic chemical raw material for plastics, rubber, and ethanol.

Polyethylene, referred to as PE.

It is a polymer of ethylene and is non-toxic. Easy to color, good chemical stability, cold resistance, radiation resistance, and good electrical insulation. It is suitable for packaging materials for food and medicines, food utensils, medical equipment, and insulation materials for the electronics industry.

Polypropylene, referred to as pp.

It is a thermoplastic resin made by polymerization of propylene. It is a non-toxic, odorless, and tasteless milky white highly crystalline polymer. It is one of the lightest varieties of all plastics.

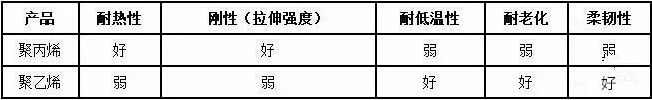

The production processes of polyethylene and polypropylene raw materials are relatively similar, and the products can be used to make plastic films, injection molded products, plastic pipes, etc. In many cases, we find that the properties and uses of the two raw materials are very similar. But in fact, there are still many differences in the application of polypropylene raw materials and polyethylene raw materials:

From the perspective of heat resistance, the heat resistance of polypropylene is higher than that of polyethylene. Under normal circumstances, the melting temperature of polypropylene is about 40%-50% higher than that of polyethylene, which is about 160-170℃, so the product can Sterilize at a temperature above 100°C, and will not deform at 150°C under the condition of no external force. In daily life, we will find that “5” polypropylene lunch boxes are often used to heat food in microwave ovens (the general temperature of microwave heating is 100-140℃), and polyethylene cannot be used as plastic for microwave ovens due to its poor heat resistance. , Including lunch boxes and plastic wrap. Similarly, in the field of ordinary packaging films, polyethylene packaging bags are more suitable for use at temperatures below 90°C, while polypropylene packaging bags can be used at relatively high temperatures.

From the perspective of rigidity and tensile strength, the main characteristics of polypropylene are low density, better mechanical properties than polyethylene, and outstanding rigidity. For example, polypropylene has gradually begun to compete with engineering plastics (PA/PC). It is widely used in the fields of electronic appliances and automobiles. At the same time, because polypropylene has high tensile strength and good bending resistance, it is called “100-fold glue”. It is folded and bent 1 million times and does not become white when bent. This also provides a clue for us to distinguish polypropylene products. Hidden signs for recycling and sorting of products.

From the perspective of low temperature resistance, polypropylene has weaker low temperature resistance than polyethylene. The impact strength at 0°C is only half of that at 20°C, while the brittleness temperature of polyethylene can generally reach below -50°C; Increase, the lowest can reach -140℃. Therefore, if the product needs to be used in a low temperature environment, it is still necessary to choose polyethylene as the raw material. Generally, trays used for refrigerated food are made of polyethylene raw materials.

From the perspective of aging resistance, the aging resistance of polypropylene is weaker than that of polyethylene. The structure of polypropylene is similar to that of polyethylene, but due to the presence of a side branched chain composed of methyl groups, it is easier to be exposed to ultraviolet light and heat. Oxidative degradation. The most common polypropylene product that is prone to ageing in daily life is the woven bag. The woven bag is easily broken when exposed to the sun for a long time. In fact, although the aging resistance of polyethylene is higher than that of polypropylene, compared with other raw materials, its performance is not very outstanding, because the polyethylene molecule contains a small amount of double bonds and ether bonds, and its weather resistance is not good. , Sun and rain can also cause aging.

From the perspective of flexibility, although polypropylene has high strength, it has poor flexibility, and technically speaking, it has poor impact resistance. Therefore, when it is used to make film products, its application field is still different from that of polyethylene. Polypropylene film is more used for surface packaging printing. In terms of pipes, simple polypropylene is rarely used for production, and cross-linked polypropylene, which is a common PPR pipe, is needed. Because ordinary polypropylene has poor impact resistance and is easy to rupture, it is necessary to add impact modifiers in practical applications, and additives should be used to improve impact resistance in applications such as bumpers.