Development and Applications of Antibacterial EHC/Cellulose Lyocell Fibers

Introduction

In recent years, natural polymers have gained considerable attention due to their biodegradability, renewability, and multifunctional properties. Among these, chitosan, a biopolymer derived from chitin, has stood out as an essential material in biomedical, pharmaceutical, and environmental applications.

However, the inherent limitations of chitosan, such as its poor solubility in water, have prompted the development of chitosan derivatives with enhanced properties. One such derivative is Ethylamine Hydroxyethyl Chitosan (EHC), which exhibits improved solubility, biocompatibility, and biological activity. In particular, EHC has demonstrated promising antibacterial properties against common pathogens like Escherichia coli (E. coli), making it a suitable candidate for various applications in the textile and biomedical industries.

This paper explores the synthesis of EHC, its solubility properties, antibacterial capabilities, and the potential application of EHC in the production of antibacterial EHC/cellulose Lyocell fibers. We will also delve into the Lyocell process, a sustainable and environmentally friendly method of fabricating fibers, and how the incorporation of EHC enhances the properties of the resulting fibers. The potential applications of these fibers in various industries will be discussed, with a focus on antimicrobial textiles.

Synthesis and Chemical Structure of EHC

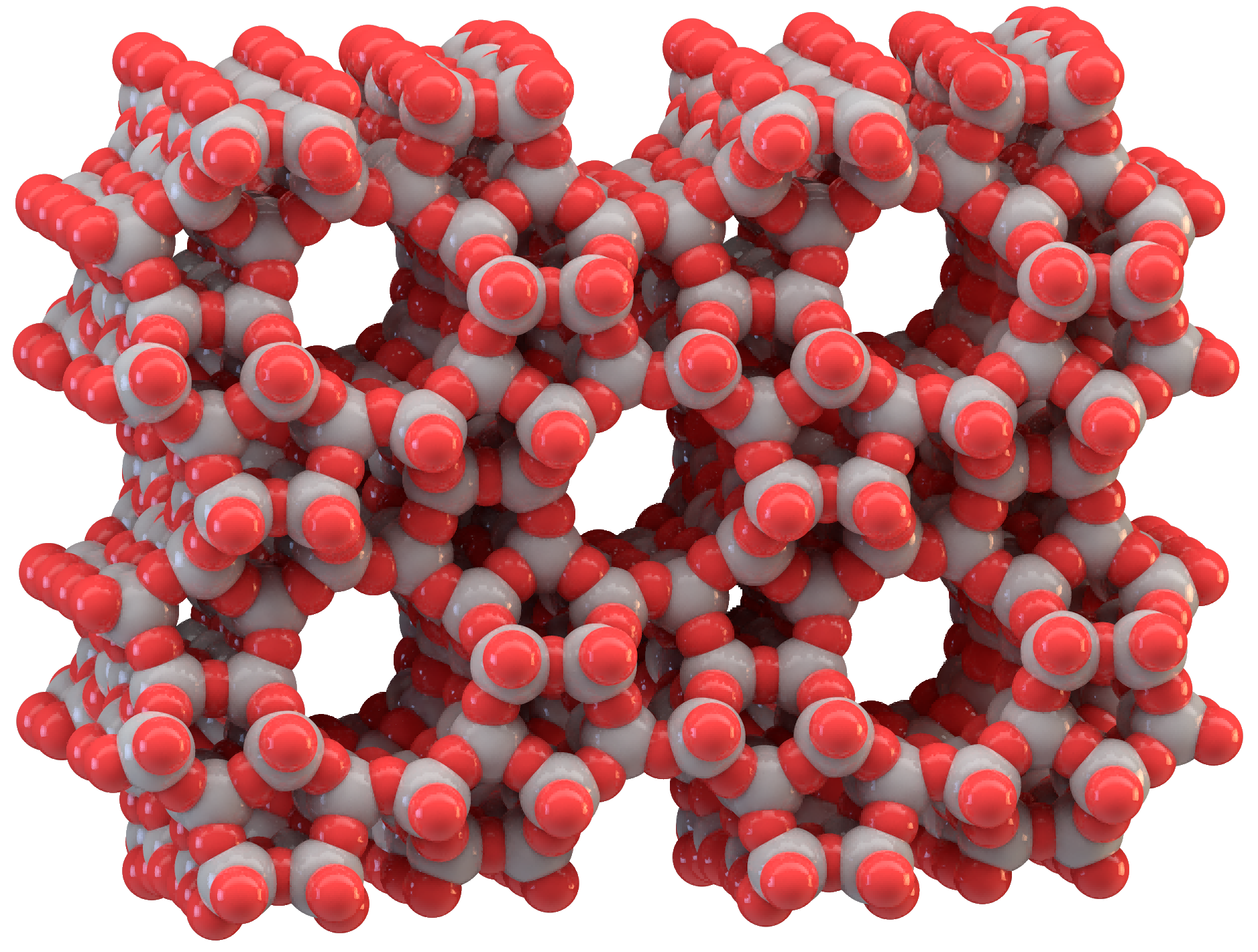

The synthesis of EHC involves modifying chitosan by introducing ethylamine and hydroxyethyl groups to its molecular structure. Chitosan itself is derived from the deacetylation of chitin, a natural polymer found in the exoskeletons of crustaceans and insects.

However, chitosan in its natural form is not water-soluble, which limits its broader application. By introducing ethylamine and hydroxyethyl groups, the solubility of chitosan is significantly enhanced, particularly in aqueous solvents such as N-methylmorpholine-N-oxide (NMMO). NMMO, a green solvent, is particularly effective for dissolving chitosan derivatives, making it an ideal choice for processing in fiber applications.

The ethylamine group imparts positive charges to the chitosan derivative, improving its solubility and hydrophilicity. This modification allows the polymer to dissolve in NMMO under controlled conditions, which is crucial for further processing into fibers.

The hydroxyethyl group enhances the chemical stability and biocompatibility of the polymer, allowing it to interact more efficiently with various substrates.

Solubility of EHC and its Role in Fiber Manufacture

One of the key advantages of EHC over native chitosan is its improved solubility in aqueous solvents, particularly NMMO. This property is critical in the context of Lyocell fiber production, where high polymer solubility is required to create high-quality, homogeneous fibers. The solubility of EHC allows it to be blended with cellulose, a natural polymer that is the primary material for Lyocell fibers.

Lyocell is produced through a solvent-based process that involves dissolving cellulose in NMMO, followed by extrusion through spinnerets to form fibers. The incorporation of EHC into this process enhances the mechanical properties and functionality of the resulting fibers.

The solubility of EHC in NMMO enables it to integrate seamlessly with cellulose, forming a composite material with superior properties compared to traditional cellulose fibers.

Antibacterial Properties of EHC

One of the most promising applications of EHC is its antibacterial activity. The introduction of ethylamine groups in the polymer backbone enhances its ability to interact with microbial cell membranes, thereby exhibiting bactericidal effects. EHC has been found to be particularly effective against Escherichia coli (E. coli), a common pathogenic bacterium that is resistant to many conventional antibiotics.

The antibacterial activity of EHC is primarily due to the electrostatic interactions between the positively charged ethylamine groups and the negatively charged cell membranes of bacteria.

This interaction disrupts the bacterial cell membrane, leading to leakage of cellular contents and eventually bacterial cell death.

Additionally, the hydroxyethyl groups in EHC contribute to its solubility and biocompatibility, ensuring that the material is safe for use in various applications, including in textiles and biomedical devices.

Development of Antibacterial EHC/Cellulose Lyocell Fiber

The integration of EHC with cellulose in the Lyocell process results in the creation of EHC/cellulose Lyocell fibers, which combine the natural advantages of cellulose fibers with the antimicrobial properties of EHC. These fibers are produced using an environmentally friendly process that does not require harsh chemicals, making them an attractive option for sustainable textile production.

In the Lyocell process, cellulose is dissolved in NMMO, and EHC is introduced into the solution before extrusion. The resulting fibers exhibit enhanced mechanical properties, such as increased tensile strength and elasticity, compared to fibers made from pure cellulose.

The addition of EHC also imparts antibacterial properties to the fibers, which can significantly reduce the growth of harmful microorganisms, especially E. coli, on the fiber surface.

These fibers have great potential in applications where hygiene and antimicrobial properties are critical, such as in medical textiles, hygiene products, and outdoor apparel. Additionally, the water retention properties of the EHC/cellulose fibers are improved, which can enhance their durability and comfort in various environmental conditions.

Properties of EHC/Cellulose Lyocell Fibers

The incorporation of EHC into cellulose fibers has been shown to improve several important properties:

Mechanical Properties: EHC enhances the tensile strength and elasticity of cellulose fibers, making them more durable and resistant to wear and tear. This makes EHC/cellulose fibers suitable for high-performance applications where mechanical durability is important.

Antibacterial Activity: The EHC component imparts antimicrobial properties to the fibers, making them effective in preventing bacterial growth. This is particularly useful in textiles that require high levels of hygiene, such as medical fabrics, surgical gowns, and sportswear.

Water Retention: The EHC/cellulose fibers exhibit better water retention compared to pure cellulose fibers, which can improve the comfort and moisture management of the textile materials. This property is especially important in activewear and healthcare textiles, where moisture control is essential.

Environmental Impact: The Lyocell process, coupled with the use of EHC, is an environmentally sustainable alternative to traditional textile production methods. The process uses NMMO, a non-toxic and biodegradable solvent, which reduces the environmental footprint of fiber production.

Applications of EHC/Cellulose Lyocell Fibers

Medical Textiles: The antibacterial properties of EHC/cellulose Lyocell fibers make them ideal candidates for use in medical textiles, including wound dressings, surgical masks, and hospital linens. The fibers can help reduce the risk of infection and improve patient outcomes.

Hygiene Products: EHC/cellulose fibers can be used in the production of diapers, sanitary napkins, and wipes. The antibacterial properties help reduce the growth of harmful bacteria, improving hygiene and comfort.

Sustainable Fashion: As consumer demand for eco-friendly products grows, sustainable textiles are gaining popularity. EHC/cellulose Lyocell fibers, being biodegradable and antimicrobial, provide a sustainable option for the fashion industry, particularly in activewear and outdoor clothing.

Environmental Applications: Due to their superior water retention and antimicrobial properties, these fibers can be used in products such as filtering materials and protective clothing for harsh environmental conditions.

Conclusion

The development of Ethylamine Hydroxyethyl Chitosan (EHC) as a chitosan derivative has opened new avenues for the fabrication of antibacterial fibers. By combining EHC with cellulose in the Lyocell process, it is possible to create EHC/cellulose fibers that exhibit enhanced mechanical properties, water retention, and antibacterial activity. These fibers are environmentally sustainable, biodegradable, and have a wide range of applications in the textile and biomedical industries.

Future research could focus on optimizing the synthesis of EHC, improving its solubility, and exploring additional applications of these fibers in various industrial sectors.