The Versatility and Advantages of Light-Curing Technology: Applications Across Industries

Light curing technology can be rapidly developed because of its own characteristics. Firstly, light curing only needs to be carried out at room temperature, which makes it possible to accommodate products that are not suitable for heat-drying methods. Secondly, in addition to increased productivity and energy savings, light-curing technology enables higher levels of coating quality, such as mechanical properties and gloss. Thirdly, the use of “solvent-free” systems eliminates the need for expensive sewage facilities. At present, light-curing technology has been widely used in chemical, mechanical, electronic, light industry, communications, automotive and other fields. Light-curing coatings include bamboo, wood flooring, decorative panels, furniture and other UV wood coatings; automotive parts, instruments, CD-ROMs, decorative panels, credit cards and other UV plastic coatings; steel antirust, color-coated steel, tin cans, cans and other UV metal coatings; decorative paper, labels, cards, written surface varnish, metallized coatings, such as UV paper coatings; photoresist, printed circuit boards, floppy (hard) disks, optical discs, photoresist, printed circuit board, soft (hard) disk, CD-ROM, video tape, magnetic tape, fiber optic, component encapsulation and other electronic industry UV coatings; glass, ceramics, stone substrate decorative UV coatings; leather decorative UV coatings and so on. Light-curing ink can meet different applications, different printing plates and printing methods. There are UV offset inks for printing magazines and all kinds of publications; UV flexo inks for printing packaging materials and self-adhesive labels; UV screen printing inks for printing soft and hard plastic bottles, paper and paper wrappings and textiles; UV gravure inks for printing banknotes; UV printing inks for spraying and painting of advertisements and so on. There are also printed circuit boards used in the manufacture of UV resist ink, UV solder resist ink, UV plugging ink, UV marking ink, UV conductive ink and so on. Light-curing adhesives can be used for laminated materials, composite materials, aviation glass, pressure-sensitive adhesive, optical materials and automotive parts bonding, encapsulation materials, peeling materials and so on. Light-curing materials can also be used in the field of information technology, such as optical fiber protection and coloring, magnetic media, optical media, etc., as well as light-curing fillings, light-curing dental film, light-sensitive decoloration, light-curing invisible and other biological and medical applications of medical materials and three-dimensional model manufacturing photocasting and other fields.

Light-curing coatings are the earliest example of large-scale successful application of light-curing technology in industry, but also the largest production and sales volume in the field of light-curing industry, the scale of which is much larger than that of light-curing inks and light-curing adhesives. The first generation of UV light-curing coatings, wood coating industry in the initial application, when the use of unsaturated polyester – styrene system, photoinitiators are mostly benzene diphenyl ether, low price, slow curing rate. The second generation of light-curing coatings to acrylate oligomer as the main resin, active diluent to acrylate monomer-based, light polymerization speed compared with the first generation greatly improved, cured material properties have been well improved.UV wood coatings are characterized by excellent paint performance, fast curing, product stability in the application of the equipment, low processing costs, organic volatiles, low or zero emissions.UV Wood UV wood coatings include UV putty paint, UV primer and UV top coat, UV wood coatings are light-curing coatings products in the production of larger varieties. UV paper coatings are suitable for books and magazines covers, postcards, advertising posters, merchandise packaging cartons, decorative paper bags, labels, cards, metallized coatings, and other paper substrate coating, which can improve the surface of the substrate gloss, protect the cover printing surface ink patterns and lettering to enhance the finish, and waterproof and dirt-resistant. UV paper coatings have become one of the largest varieties of light-curing coatings in the output, and high-gloss UV paper varnish for paper varnish coatings output of the largest varieties.

Applications of Light-Curing Coatings

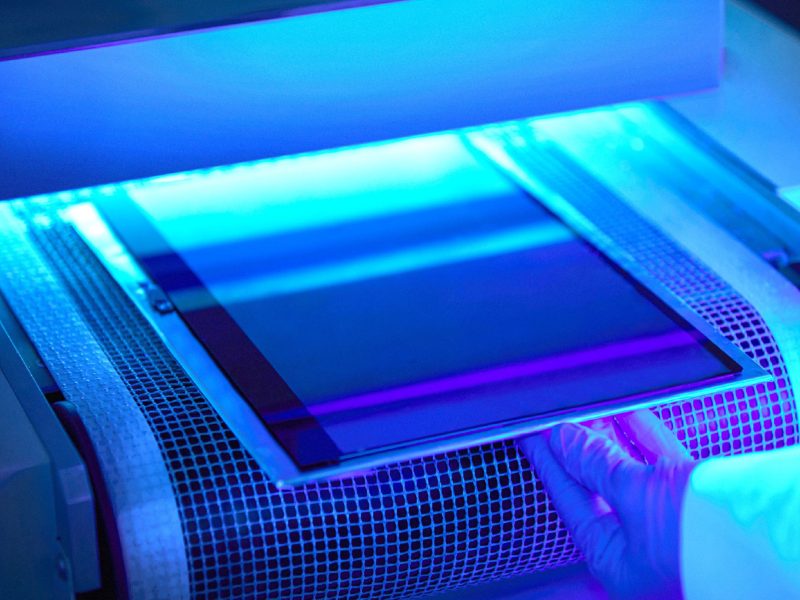

1.Electronics Industry

In the electronics industry, light-curing coatings are used for protective coatings, encapsulants, and adhesives. They offer rapid processing times, essential for high-throughput manufacturing environments. These coatings provide excellent protection against environmental factors such as moisture, chemicals, and mechanical abrasion, making them ideal for use in printed circuit boards (PCBs) and other sensitive electronic components.

2.Automotive Industry

The automotive sector utilizes light-curing coatings for various applications, including clear coats, interior trim coatings, and protective films. Their fast curing times are particularly advantageous in automotive assembly lines, where speed and efficiency are paramount. Moreover, these coatings provide superior durability, UV resistance, and a high-quality finish, which are critical for automotive applications.

3.Medical Devices

In the medical field, light-curing coatings are used for devices and instruments that require biocompatibility, chemical resistance, and sterilization stability. They are commonly applied in coatings for catheters, surgical instruments, and dental materials. The ability to cure rapidly without the need for solvents makes light-curing coatings ideal for use in cleanroom environments, where contamination must be minimized.

4.Industrial Coatings

Industrial applications of light-curing coatings include metal coatings, wood finishes, and plastic coatings. These coatings provide excellent adhesion, chemical resistance, and mechanical properties, making them suitable for demanding industrial environments. Additionally, their rapid curing times enable increased production efficiency and reduced downtime, which is critical in industrial manufacturing.

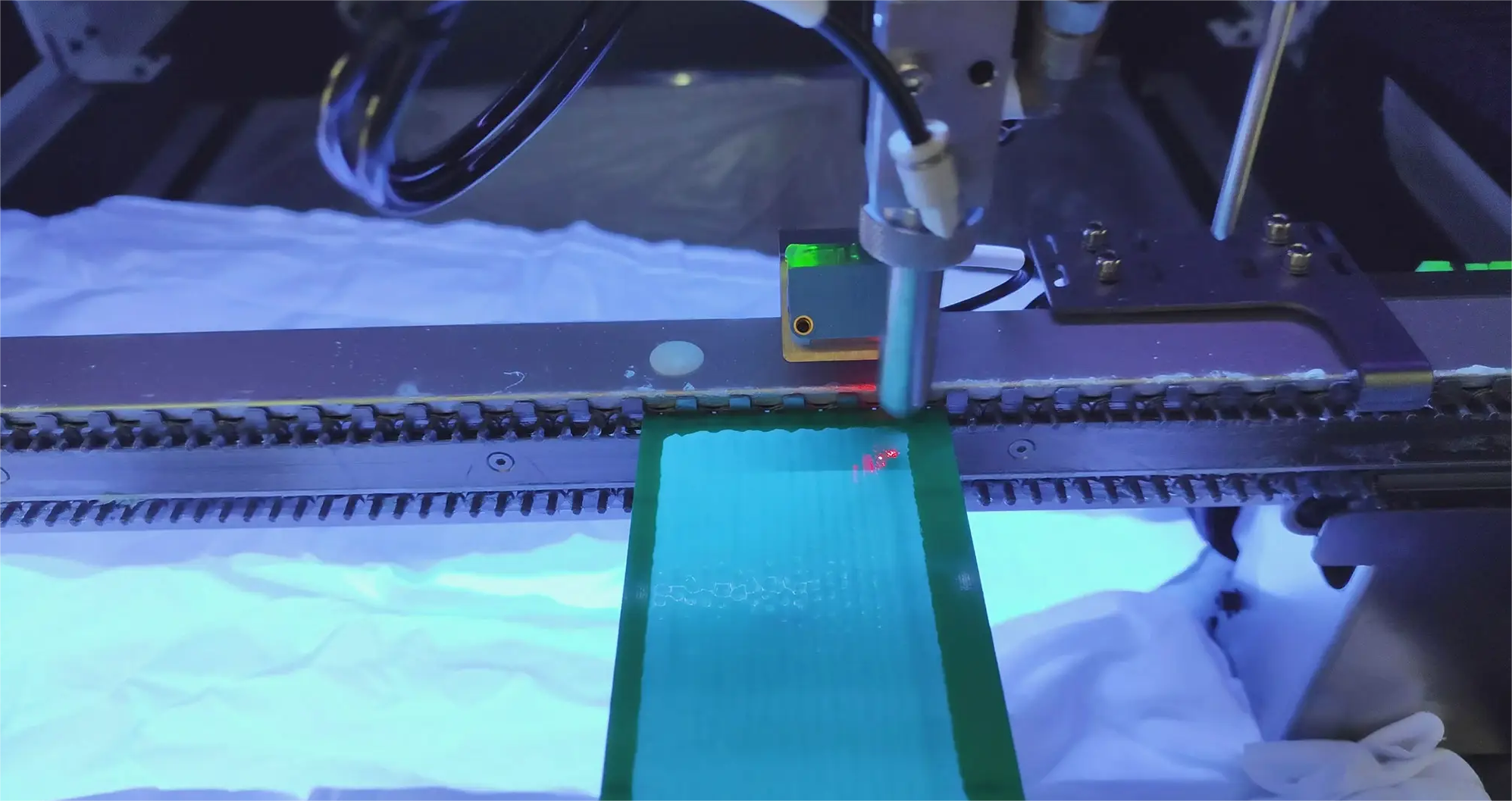

5.Graphic Arts and Printing

In the graphic arts and printing industries, light-curing coatings are used for varnishes, inks, and adhesives. They allow for high-speed printing processes and provide high gloss, clarity, and durability, making them ideal for labels, packaging, and other printed materials. The environmental benefits of UV-curable inks, including low VOC emissions, have also driven their adoption in this sector.