1.Synthesis and Production

A. Raw materials

Primary precursors:

a) 2,5-Dimethylaniline (C8H11N)

b) Succinic acid (C4H6O4) or succinic anhydride (C4H4O3)

Secondary reagents and catalysts:

a) Polyphosphoric acid (PPA) as condensing agent and solvent

b) Sodium nitrite (NaNO2) for diazotization

c) Copper(I) chloride (CuCl) as catalyst for cyclization

Solvents and processing aids:

a) N-Methylpyrrolidone (NMP) for purification

b) Methanol for precipitation and washing

B. Synthesis process

Condensation reaction:

a) 2,5-Dimethylaniline reacts with succinic acid in PPA at 80-100°C

b) Formation of 2,5-diarylaminoterephthalic acid intermediate

c) Reaction time: 4-6 hours under controlled stirring

Ring closure:

a) Temperature increase to 150-180°C

b) Intramolecular cyclization to form quinacridone structure

c) Duration: 2-4 hours with careful temperature control

Oxidation:

a) Addition of sodium nitrite at 80-90°C

b) Oxidation of leuco quinacridone to final quinacridone pigment

c) Reaction time: 1-2 hours with precise pH control (pH 1-2)

Crystal phase control:

a) Heating in high-boiling solvent (e.g., N-methylpyrrolidone) at 200-220°C

b) Conversion to γ-phase crystal modification

c) Duration: 2-4 hours under reflux conditions

C. Purification methods

Filtration and washing:

a) Hot filtration to separate crude pigment

b) Multiple washing steps with water and methanol

c) Acid treatment to remove metal impurities

Solvent treatment:

a) Extraction with NMP to remove organic impurities

b) Reprecipitation by addition to cold water

Milling and classification:

a) Wet milling to achieve desired particle size distribution

b) Classification using hydrocyclones or centrifuges

D. Post-synthesis treatments

Surface treatment:

a) Application of surfactants or resins to improve dispersibility

b) Typical agents: Fatty acid derivatives, polyethylene glycols

Particle size adjustment:

a) Jet milling for ultra-fine particles

b) Controlled aggregation for specific applications

2.Applications

A. Coatings and paints

Automotive finishes

a) High-end metallic and pearlescent finishes

b) Clear coat systems for enhanced durability

c) Color-shifting effects when combined with interference pigments

Industrial coatings

a) Heavy machinery and equipment coatings

b) Appliance finishes

c) Aerospace coatings for both exterior and interior applications

Architectural paints

a) Premium interior wall paints

b) Exterior facade coatings with high weather resistance

c) Wood stains and varnishes for decorative purposes

B. Plastics coloration

Engineering plastics

a) Polyamides (PA) for automotive components

b) Polyoxymethylene (POM) for precision parts

c) Polycarbonate (PC) for electronic housings

Consumer goods

a) Household appliances and kitchenware

b) Toys and sporting goods

c) Personal care product packaging

C. Printing inks

Packaging inks

a) Flexographic inks for flexible packaging

b) Gravure inks for high-quality packaging

c) UV-curable inks for specialty packaging

Publication inks

a) Sheet-fed offset inks for high-end magazines

b) Heat-set web offset inks for catalogs and brochures

Security printing

a) Banknote inks

b) Anti-counterfeiting features in official documents

D. Artists’ colors

Oil paints for fine art

Acrylic paints for both professional and hobby use

Watercolors and gouache

Colored pencils and pastels

E. Textile printing and dyeing

Direct printing on natural and synthetic fabrics

Dye sublimation printing for polyester fabrics

Pigment dyeing for denim and other heavy fabrics

F. Cosmetics and personal care products

Nail polishes and nail art products

Eye shadows and other color cosmetics

Hair dyes and temporary hair color products

G. Emerging applications

Solar cells

a) Organic photovoltaics as a sensitizer

b) Dye-sensitized solar cells (DSSCs) for improved light absorption

Organic electronics

a) Organic light-emitting diodes (OLEDs) for displays

b) Organic field-effect transistors (OFETs)

Biomedical applications

a) Fluorescent markers for cellular imaging

b) Photodynamic therapy agents

H. Specialty papers and cardboards

High-quality gift wrapping papers

Luxury packaging papers

Artist-grade colored papers

I. Ceramics and glass coloration

Ceramic glazes for decorative tiles

Glass enamels for architectural glass

Colored glass for art and decoration

J. 3D printing materials

Colorants for ABS and PLA filaments

Pigments for SLA and DLP resins

Color agents for powder-based 3D printing

K. Rubber and elastomer coloration

Colored rubber flooring

Automotive rubber components

Sporting goods (e.g., yoga mats, exercise bands)

L. Concrete and construction materials

Colored concrete for decorative applications

Pigmented grouts and mortars

Coloration of synthetic stones

M. Functional coatings

Anti-corrosion coatings with color-indicating properties

Heat-reflective coatings for energy efficiency

Antimicrobial coatings with aesthetic appeal

N. Digital printing

Inkjet inks for large format printing

Toners for digital laser printers

Dye-sublimation printing for textiles and hard surfaces

O. Color filters

LCD displays

Optical filters for scientific instruments

Lighting gels for stage and film production

3.Performance Characteristics

A. Color strength and brilliance

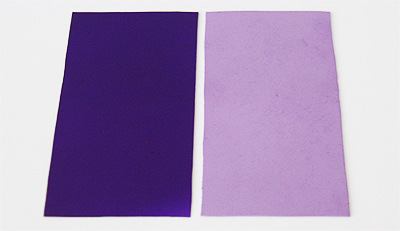

Tinting strength

a) High tinting strength with a tinting strength index of 115-125 compared to standard

b) Excellent color development in various media

c) Ability to achieve deep shades with relatively low pigment loading

Masstone characteristics

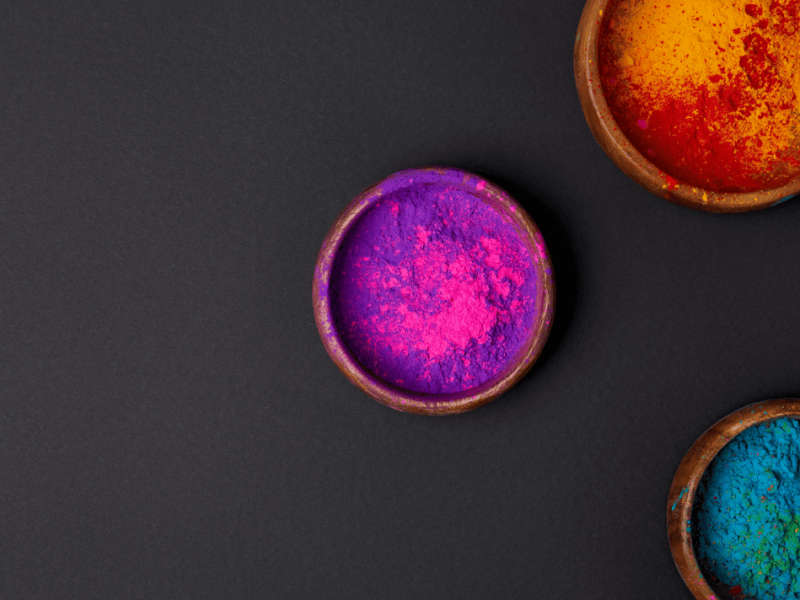

a) Rich, vibrant violet color in full strength applications

b) Slight reddish undertone contributing to its unique shade

Undertone properties

a) Clean, slightly bluish undertone in tint reductions

b) Consistent undertone across different application media

Chroma and saturation

a) High chroma values, typically 70-75 in CIELAB color space

b) Excellent color saturation, maintaining vibrancy even in deep shades

B. Dispersibility in various media

Organic solvents

a) Excellent dispersibility in polar organic solvents

b) Moderate dispersibility in non-polar solvents, may require dispersing agents

Water-based systems

a) Good dispersibility in water with appropriate surfactants

b) Stable dispersion in aqueous coating formulations

Polymers and resins

a) High compatibility with a wide range of polymer systems

b) Easy incorporation into thermoplastics and thermosets

Dispersion stability

a) Low tendency for flocculation in properly dispersed systems

b) Minimal color float and good color consistency

C. Heat resistance

Thermal stability

a) Excellent color stability up to 280-300°C in most polymer systems

b) Minimal color shift at elevated temperatures

Processing stability

a) Withstands high-temperature processing in plastics (e.g., injection molding)

b) Suitable for high-temperature cure coatings

D. Chemical resistance

Acid resistance

a) Excellent stability in acidic environments (pH 2-7)

b) Minimal color change or degradation in presence of weak to moderate acids

Alkali resistance

a) Good stability in alkaline conditions (pH 7-12)

b) Slight color shift may occur in strongly alkaline environments

Solvent resistance

a) High resistance to common organic solvents

b) Excellent bleed resistance in solvent-based systems

Oxidation and reduction resistance

a) Good stability against oxidizing agents

b) Moderate resistance to strong reducing agents

E. Opacity/transparency

Opacity in full shade

a) Medium to high opacity in masstone applications

b) Hiding power increases with pigment concentration

Transparency in tints

a) Good transparency in tint reductions

b) Suitable for transparent effect finishes and glazes

Influence of particle size

a) Finer particle sizes increase transparency

b) Larger particles or aggregates enhance opacity

F. Lightfastness and weatherability

Lightfastness

a) Excellent lightfastness (8/8 on the Blue Wool Scale)

b) Minimal fading under prolonged exposure to UV light

Weatherability

a) Outstanding weather resistance (typically 5/5 on standard scales)

b) Excellent retention of color and gloss in exterior applications

UV stability

a) High resistance to UV-induced degradation

b) Minimal chalking or color change in outdoor exposures

Below is our Permanent Violet RL product page