Master Your Ink: The Crucial Role of Additives in Water-based Plastic Ink

In the modern printing industry, the shift towards eco-friendly solutions has placed Water-based Plastic Ink in the spotlight. However, achieving elite Performance with these inks requires a scientific touch. How do you ensure vibrant colors, flawless application, and consistent quality on every run? The answer lies in the masterful use of Additives.

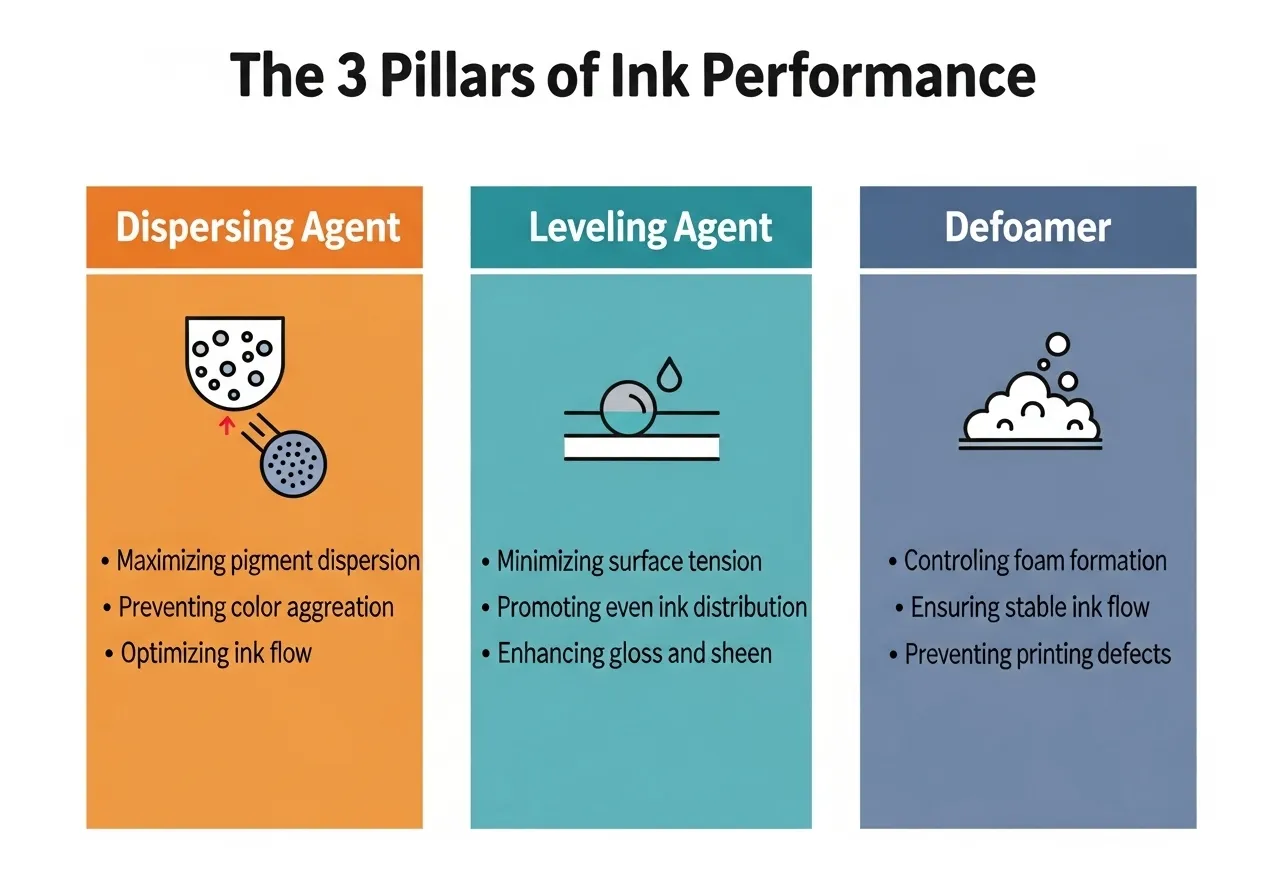

While used in minuscule amounts, these powerful agents are the unsung heroes of ink formulation. They play a vital role during both the manufacturing and printing processes, enhancing specific properties to overcome common challenges. This article explores three of the most essential additives—the Dispersing Agent, Leveling Agent, and Defoamer—that elevate good ink to great ink.

Dispersing Agent: The Foundation of Color and Stability

A Dispersing Agent is fundamental to achieving vibrant, stable color. Its primary role is to ensure that the solid pigment particles in the ink are evenly distributed and remain separated within the liquid base.

A dispersing agent works by thoroughly wetting the surface of each pigment particle. This process imparts an electrical charge onto the particle surfaces, creating a repulsive force that prevents them from clumping together (agglomeration). For Water-based Plastic Ink to have excellent Dispersibility, a sufficient amount of the correct dispersing agent is non-negotiable.

- Key Benefits:

- Prevents pigment settling during storage.

- Ensures consistent color strength and viscosity.

- Greatly improves the long-term Stability of the ink.

Illustrative Example: Think of trying to mix fine, insoluble powder into water; it quickly settles at the bottom. A dispersing agent acts like a protective bubble around each particle, keeping them suspended and creating a smooth, homogenous mixture. According to a 2023 industry report, a well-formulated dispersion can improve color strength by over 10% and significantly extend the ink’s shelf life.

Leveling Agent: For a Flawless, High-Gloss Finish

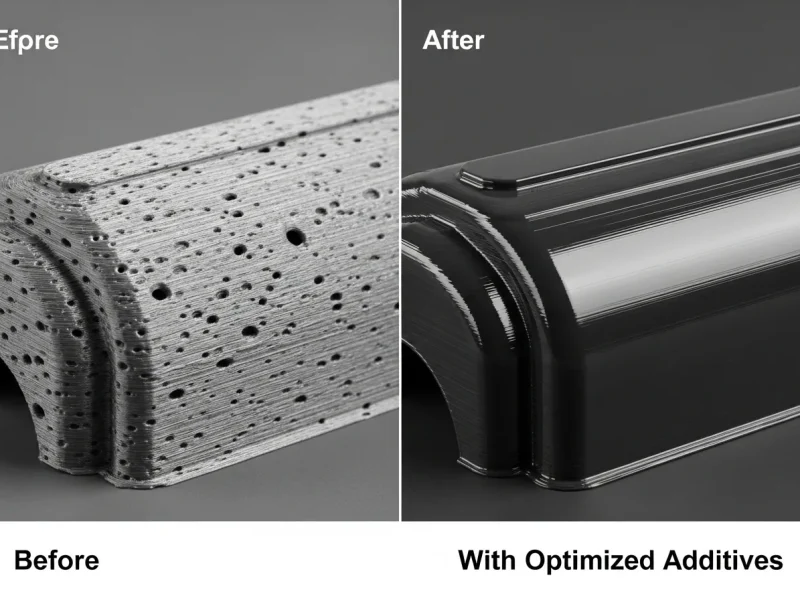

The final appearance of a printed product is paramount. A Leveling Agent is used to eliminate and reduce Surface Defects after the ink is applied to the Substrate, ensuring the final film is smooth, even, and glossy.

This additive works by reducing the surface tension of the wet ink, allowing it to flow out and “level” itself before drying. This action corrects imperfections like brush marks, cratering, or “orange peel” textures. It also improves the ink’s Wettability, helping it spread evenly across the substrate for superior coverage and adhesion.

Case Study: A packaging converter printing on flexible plastic film was experiencing inconsistent gloss and micro-craters in their final prints. By incorporating a targeted leveling agent into their Water-based Plastic Ink, they enhanced the ink’s flow across the non-porous substrate. The result was the elimination of surface defects and a 20% increase in gloss, meeting the high-end cosmetic brand’s strict quality standards.

Defoamer: Ensuring Perfect Printing Quality

During the mixing and high-speed application of ink, agitation can introduce air, creating Bubbles/Foam. This seemingly small issue can wreak havoc on Printing Quality. A Defoamer is the essential additive designed to combat this problem.

Foam and trapped air bubbles can cause numerous problems:

- Pinholes or voids in the dried ink film.

- Inaccurate color density.

- Poor pigment Dispersibility and ink transfer.

- Overall reduction in print quality, leading to wasted materials and time.

Adding a small, precise amount of a defoamer effectively neutralizes this threat. It works by migrating to the surface of the bubbles and rupturing them, preventing foam from forming or quickly eliminating it if it does.

Why It Matters: Studies in fluid dynamics show that even a minuscule 0.2% concentration of entrapped air in an ink system can lead to measurable defects in high-speed printing. This highlights the critical importance of an effective defoamer for maintaining operational efficiency and product integrity.

Small Additions, Monumental Impact

It is clear that Additives are not just optional extras; they are essential components that unlock the full potential of Water-based Plastic Ink. From the foundational Stability provided by a Dispersing Agent, to the perfect finish guaranteed by a Leveling Agent, and the defect-free application ensured by a Defoamer, each plays a critical and irreplaceable role.

Navigating the vast world of additives to find the perfect match for your specific ink formulation and Substrate can be complex. The right choice depends on your equipment, desired finish, and performance requirements.