How to Select the Right Coating Leveling Agent for a Flawless Finish

Have you ever wondered how industrial coatings achieve that perfectly smooth, glass-like finish? The secret often lies in a small but critical component: the leveling agent. Selecting the right leveling agent for your coating formula is a crucial step that directly impacts the final appearance and performance of the film. An incorrect choice can lead to frustrating surface defects, while the right one ensures a pristine, functional surface.

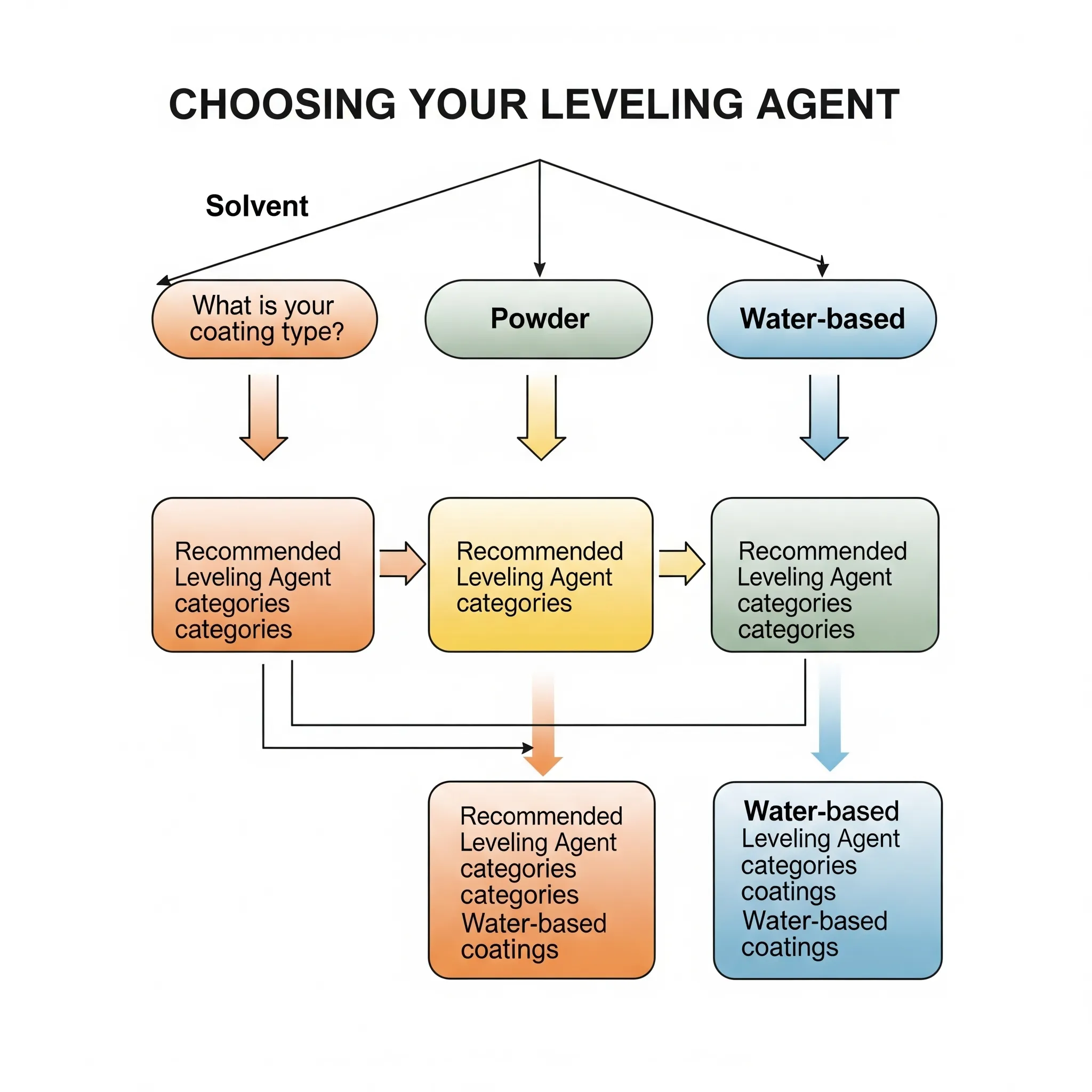

This guide will walk you through how to select the ideal leveling agent by exploring the unique demands of solvent-based, powder, and water-based coating systems.

Choosing Leveling Agents for Solvent-Based Coatings

Solvent-based systems require a nuanced approach, as the needs of a primer differ greatly from those of a topcoat.

![]()

Primers and Mid-Coats: Building a Strong Foundation

For primers and intermediate coats, acrylic leveling agents are the industry standard.

- For Degassing and Wettability: If your primary concerns are good degassing and substrate wettability, choose a medium-to-high molecular weight acrylic leveling agent.

- For Enhanced Wetting: On challenging or low-energy substrates, you may need more power. Consider agents that significantly reduce surface tension, such as silicone leveling agents or modified acrylics like fluorine-modified acrylic leveling agents and phosphate-modified acrylic leveling agents.

A word of caution: silicones and fluoro-modified acrylics can sometimes cause issues with foam stability or inter-coat adhesion. In a 2023 case study, an automotive parts manufacturer facing adhesion problems on an oily metal substrate found their solution in a phosphate-modified acrylic leveling agent. It provided the necessary wetting without the side effects, perfecting their primer application.

Topcoats and Clearcoats: Achieving a Perfect Appearance

When the final appearance is paramount, a low molecular weight acrylic leveling agent is generally preferred. This choice promotes excellent leveling and helps prevent haze or cloudiness in the final film.

For applications demanding superior slipperiness and scratch resistance, a silicone leveling agent is essential, often used in combination with an acrylic agent. Interestingly, on vertical surfaces, silicone agents not only improve flow but also effectively prevent sagging.

Here is a comparison table of Acrylic, Silicone, and Modified Acrylic leveling agents across key performance metrics:

| Feature | Acrylic | Silicone | Modified Acrylic |

| Leveling | Good at reducing short-wave defects (orange peel). | Excellent at reducing surface tension for a very smooth finish. | Very good to excellent, often providing a balance between the properties of acrylics and silicones. |

| Substrate Wettability | Moderate. Generally higher surface tension than silicones, so less effective on contaminated or low-energy substrates. | Excellent due to significant reduction in surface tension. | Good to Excellent. The modification (e.g., with silicone or fluorine) enhances wetting properties compared to standard acrylics. |

| Degassing | Good, especially with higher molecular weight acrylics. Helps to release trapped air during application and curing. | Fair. Can sometimes stabilize foam, leading to pinholes or other defects. | Good. Often designed to have good degassing properties while still providing some of the benefits of silicones. |

| Slipperiness | Low. Does not significantly increase surface slip. | High. Creates a very slippery surface, which can improve scratch and mar resistance. | Moderate to High. The degree of slipperiness depends on the specific modification. |

| Potential Side Effects | Minimal. Generally good compatibility and less likely to cause issues with recoating. | Can cause surface defects like craters and fisheyes if not used correctly. Can also lead to problems with intercoat adhesion and may contaminate work areas. | Can have some of the same issues as silicones, such as cratering and recoatability problems, but these are often less severe due to the acrylic backbone. |

Selecting Leveling Agents for Powder Coatings

The leveling process for powder coatings occurs in two stages: the melting of powder particles and their subsequent flow into a uniform film. Since no solvents are present, substrate wettability is the most critical factor.

- Primary Choice: Acrylic leveling agents are the most common choice. Liquid agents must be processed into a masterbatch first, but user-friendly powder-form acrylics—where the agent is adsorbed onto silica—are widely available.

- For Durability: If the goal is to enhance slipperiness and scratch resistance, a specialized powdered silicone leveling agent should be incorporated.

Pro Tip: When using silicone additives in powder coatings, carefully manage the dosage. While they boost performance, overuse can lead to surface defects like pitting or craters. Running tests to find the optimal concentration is key.

Navigating Leveling Agents for Water-Based Coatings

Water-based systems present their own unique challenges due to the high surface tension of water. The strategy depends on whether the system is water-soluble or a latex emulsion.

Water-Soluble Systems

These systems require a significant reduction in surface tension. Silicone leveling agents and fluorocarbon leveling agents are highly effective for this purpose. However, to achieve a truly flat and smooth surface, incorporating an acrylic leveling agent designed for aqueous systems is still a necessity.

Latex Emulsion Systems

Latex paints form a film through a different mechanism, and their viscosity behavior is distinct. While leveling agents can improve substrate wettability and acrylic leveling agents contribute to a smoother finish, the primary control of flow and leveling comes from rheology modifiers.

Think of it this way: the rheology modifier is like the road system that directs the main flow, while the leveling agent is the final paving crew that ensures the surface is perfectly smooth.

Make the Right Selection for Flawless Results

Choosing the correct leveling agent isn’t just about preventing defects—it’s about unlocking the full potential of your coating. The ideal choice always depends on your specific formulation, application method, and desired end properties.

Navigating the world of coating additives can be complex. If you have questions about which leveling agent is right for your specific application or need help troubleshooting a surface defect, our experts are here to help.

Contact us today for a consultation and let us help you select the perfect solution for your needs.