Unlcking Potential: Key Industrial Uses of Acrylic Resins

Have you ever wondered what gives your car its glossy, weather-resistant finish or what makes modern paints so durable? The answer often lies in a powerful and versatile polymer: acrylic resin. Acrylic resins, a broad family of polymers derived from acrylate and methacrylate esters, are the unsung heroes in countless industries. By carefully selecting the resin structure, formulation, and production process, we can create a vast range of materials tailored for specific needs.

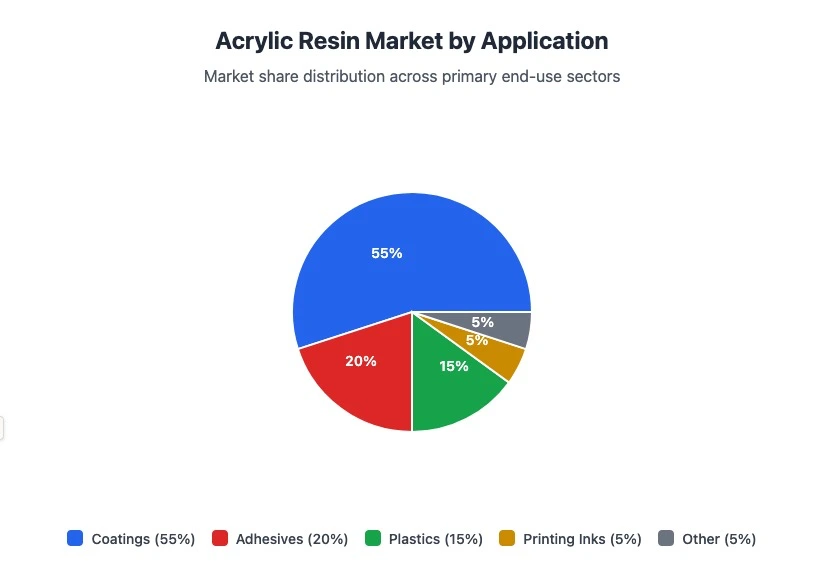

The primary applications for these remarkable polymers are in high-performance coatings, strong adhesives, vibrant printing inks, and durable plastics. Their success stems from a key characteristic: acrylic resins have a main absorption peak outside the solar spectrum, granting them exceptional light and outdoor aging resistance. This makes them indispensable in demanding fields like automotive, construction, and electronics. The two main categories, thermoplastic acrylics and thermosetting acrylics, offer unique properties for these diverse applications.

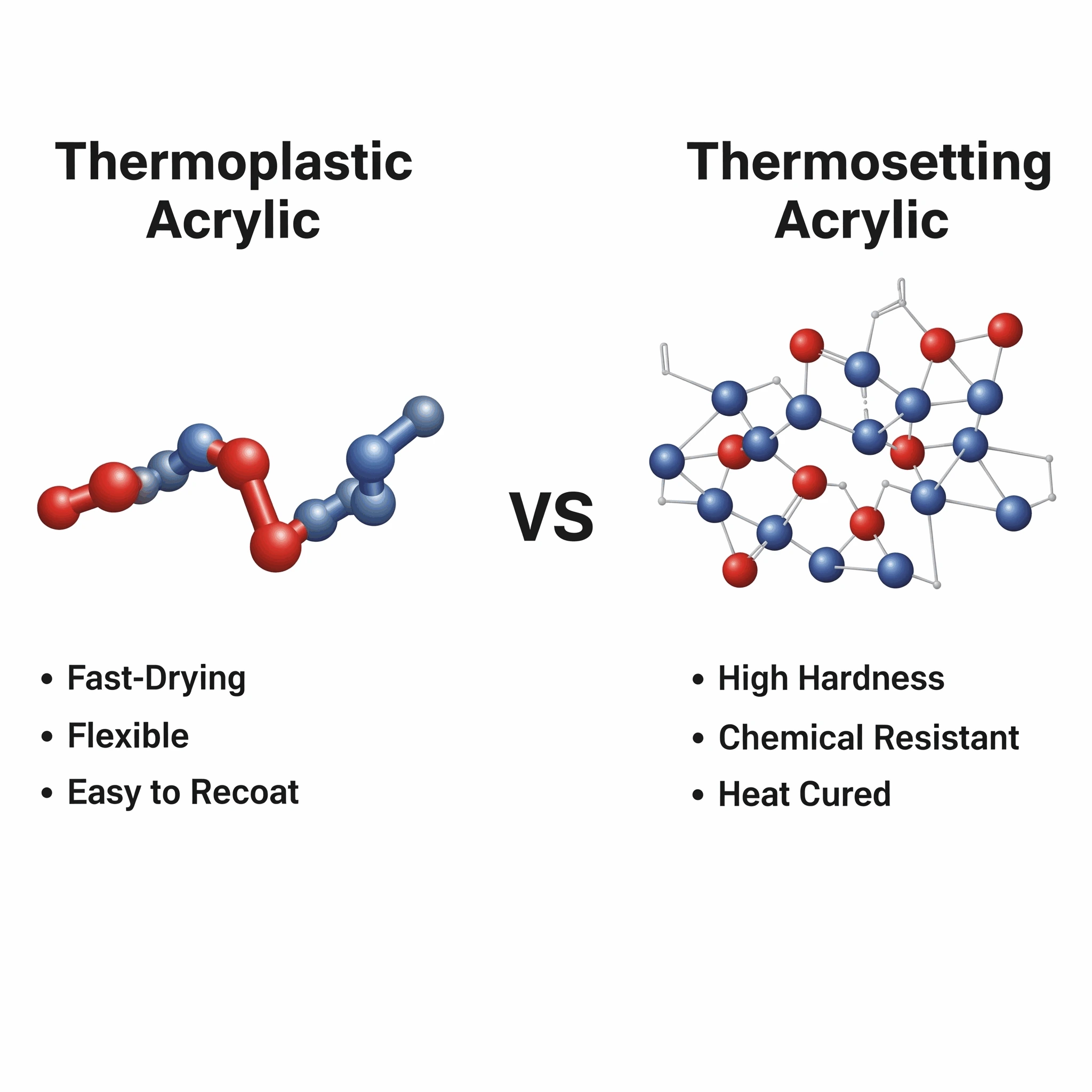

Thermoplastic vs. Thermosetting Acrylics: What’s the Difference?

Understanding the distinction between thermoplastic and thermosetting acrylics is key to appreciating their wide-ranging uses. The choice between them depends entirely on the performance requirements of the final product.

Flexible and Fast-Drying: Thermoplastic Acrylics

Thermoplastic acrylics are prized for their convenience and performance. During the film-forming process, they do not undergo further chemical cross-linking. This means they are fully reacted polymers that form a film simply through solvent evaporation.

- Key Properties:

- Excellent gloss and color retention.

- High resistance to water and chemicals.

- Fast-drying, which speeds up production lines.

- Easy to re-coat or repair, making them ideal for maintenance.

A notable application is in automotive coatings for refinishing and in the formulation of metallic paints, where they ensure excellent alignment and brightness of aluminum flakes. They are also a cornerstone of architectural coatings, protecting buildings from the elements.

Durable and Resilient: Thermosetting Acrylics

Thermosetting acrylics, on the other hand, are designed for maximum durability. These resins have a lower molecular weight initially and contain functional groups in their structure. During application, they react (or cross-link) with other resins—such as amino or epoxy resins—when heat is applied, forming a permanent, robust network.

- Key Properties:

- Superior fullness, gloss, and hardness.

- Excellent resistance to solvents and weathering.

- Non-yellowing and color-stable, even when baked at high temperatures.

The most significant use is in amino-acrylic baking paints. According to industry reports, this segment is a major consumer of thermosetting acrylics, driven by the automotive and appliance industries.

- Case Study Example: The factory finish on a new car or motorcycle is a prime example. An amino-acrylic baking paint provides the deep gloss and hardness needed to protect the vehicle’s body from scratches, UV radiation, and environmental pollutants for years. This same technology is also used for rolled steel coatings on building panels and appliances.

Core Applications Across Industries

From protecting surfaces to bonding components, acrylic resins are foundational materials in modern manufacturing.

High-Performance Coatings

Coatings represent the largest market for acrylic resins. Their versatility allows for formulations ranging from protective industrial layers to decorative house paints.

- Spray Coatings: These are valued for their ability to create smooth, even finishes on various substrates, offering excellent water, pollution, and weather resistance. They are used extensively for furniture coatings and protecting industrial machinery.

- Water-Based Coatings: As environmental regulations tighten, the demand for low-VOC water-based coatings has surged. These eco-friendly options provide outstanding gloss, adhesion, and flexibility, making them perfect for both indoor and outdoor architectural use.

Versatile and Strong Adhesives

In the world of adhesives, acrylic resins are celebrated for their strength and reliability. They create powerful bonds and can be customized to suit different materials and environments. Their advantages include excellent initial adhesion, high bond strength, and impressive resistance to chemicals.

- Illustrative Example: In electronics manufacturing, acrylic adhesives are used for the metal bonding of components inside a smartphone and for securing the electronics housings. They provide a bond that is not only strong but also resists heat and humidity, ensuring the device’s longevity. This makes them perfect for creating chemical-resistant adhesives for industrial settings.

Vibrant Printing Inks

Acrylic resins are a vital component in printing inks, known for their fast-drying properties and excellent adhesion. This allows for high-speed printing on a variety of materials.

- Paper Inks: Used in high-quality packaging and publications.

- Plastic Inks: Formulated for excellent adhesion on non-porous plastic films and containers.

Durable and Weather-Resistant Plastics

When used as the primary monomer, acrylics create plastics with exceptional properties. These materials are known for their outstanding weather resistance, optical clarity, good insulation, and strong water repellency. This makes them ideal for manufacturing:

- Automotive parts (e.g., headlight and taillight covers)

- Industrial components

- Durable electronics housings

- Building materials and household goods

The world of acrylic resins is vast, with formulations that can be tailored to almost any industrial challenge. From creating brilliant, long-lasting coatings to formulating powerful adhesives and robust plastics, the possibilities are nearly endless.

Navigating these options to find the perfect solution for your product can be complex. If you have questions about a specific application, don’t understand the technical specifications, or need guidance on selecting the right resin, our team of experts is here to help.

Click to view our catalog.