UV Curing Adhesive: The Ultimate Guide to Speed and Precision

In modern manufacturing, efficiency and precision are paramount. What if you could bond components not in minutes or hours, but in mere seconds? This is the transformative power of UV curing adhesive. Also known as UV adhesive or, for its flawless finish, shadowless adhesive, this advanced material is an environmentally friendly bonding solution that cures only when exposed to ultraviolet light. It serves not just as a powerful adhesive but also as a foundational component in high-performance paints, coatings, and inks.

Understanding the Light Curing Mechanism

At its core, the light curing mechanism of a UV curing adhesive is a marvel of chemistry, triggered by specific ultraviolet wavelengths, typically in the 100-400nm range. The process relies on special molecules called photoinitiators.

When exposed to a UV light source, these photoinitiators instantly absorb the energy and initiate a chain reaction. This reaction causes the liquid monomers and oligomers in the adhesive to polymerize, cross-link, and solidify. The result is a tough, durable bond formed almost instantly.

Main Types of UV Curing Adhesives

UV adhesives are primarily categorized based on their curing chemistry. Understanding these differences is key to selecting the right product for your application.

Free-Radical Type

The most common and cost-effective option, free-radical type adhesives cure extremely quickly upon exposure to UV light. They are ideal for applications where speed is the top priority and the adhesive is applied in thin layers.

Cationic Type

Cationic type adhesives offer unique advantages, including lower shrinkage and excellent adhesion to a variety of substrates. A key feature is their ability to continue curing even after the UV light source is removed (a “dark cure”), which is perfect for bonding opaque materials or complex geometries where light cannot reach every area.

Why Choose UV Curing Adhesives? Key Features & Advantages

The shift towards UV curing technology is driven by a host of compelling benefits that directly impact productivity, cost, and product quality.

- Incredible Curing Speed: With cure times ranging from a few seconds to under a minute, these adhesives are perfect for automated adaptability. This rapid process drastically increases throughput on production lines.

- Superior Energy Efficiency and Environmental Protection: UV curing is a room-temperature process. According to industry reports, producing 1g of UV pressure-sensitive adhesive requires only 1% of the energy needed for a water-based equivalent and 4% of a solvent-based one. Compared to traditional heat-curing methods, the energy savings can be as high as 90%.

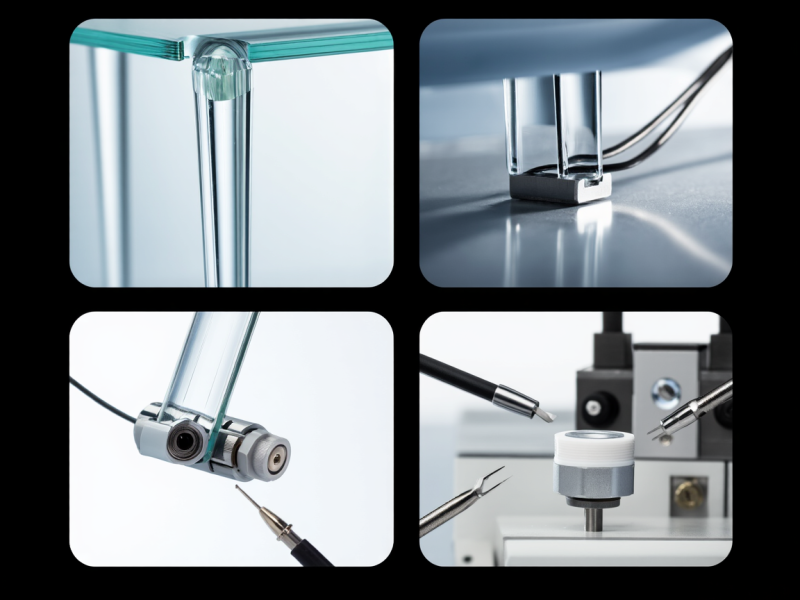

- Exceptional Bonding Versatility: UV adhesive forms incredibly strong, structural bonds on a wide range of materials, including glass, metals, plastics, and ceramics—even bonding dissimilar substrates with ease.

- Flawless Optical Properties: Its high transparency and non-yellowing characteristics are why it’s called shadowless adhesive. It’s the go-to choice for bonding glass and clear plastics where aesthetic perfection is non-negotiable.

- Simplicity and Process Control: As one-component systems, they require no mixing, simplifying application and reducing the potential for error. The curing process is fully controllable; you decide exactly when the bond is formed.

Real-World Success: Case Studies

-

Electronics Manufacturing: A leading smartphone manufacturer uses a UV curing adhesive to bond the cover glass to the OLED display. The rapid curing speed allows for precise alignment and immediate handling, while the superior optical properties ensure a crystal-clear, bubble-free view.

-

Medical Device Assembly: In the production of medical-grade catheters, a cationic type UV adhesive is used to bond a plastic hub to the tube. Its solvent-free nature ensures biocompatibility, and its ability to cure in shadowed areas guarantees a complete and secure bond, meeting stringent FDA safety standards.

From its remarkable speed and energy efficiency and environmental protection to its bonding versatility, UV curing adhesive represents a significant leap forward in adhesive technology. It empowers manufacturers to create better products faster and more sustainably.

Navigating the world of advanced adhesives can be complex. Do you have a specific application in mind or need help selecting the right free-radical type or cationic type adhesive for your project? Our team of experts is here to provide the answers you need.

Contact us today for a professional consultation or to request a product sample. Let’s build something better, together.