Hydroxyethyl Methacrylate (HEMA): A Cornerstone Acrylate Monomer for Diverse Applications

Hydroxyethyl Methacrylate, commonly known as HEMA, stands as a pivotal organic polymer monomer in the world of specialty chemicals. As one of the most widely utilized Acrylate Monomers, HEMA’s unique properties, including its notable Dual Cure Reaction capabilities, make it indispensable across a vast spectrum of industries. From advanced medical devices to high-performance automotive coatings, HEMA’s versatility continues to drive innovation. This article delves into the characteristics, applications, and market landscape of this remarkable compound.

What is Hydroxyethyl Methacrylate (HEMA)?

Hydroxyethyl Methacrylate (CAS No. 868-77-9), or HEMA, is an organic compound with the chemical formula C₆H₁₀O₃. It is primarily produced through the reaction of ethylene oxide (EO) with methacrylic acid (MAA). Structurally, HEMA is an ester of methacrylic acid and ethylene glycol.

The defining feature of HEMA is the presence of both a methacrylate group and a hydroxyl (-OH) group in its molecule. The methacrylate group, with its reactive vinyl double bond, allows HEMA to readily undergo polymerization, especially when initiated by light or heat. This process typically involves the formation of active free radicals, making HEMA one of the more reactive and easily polymerizable Acrylate Monomers. The hydroxyl group, on the other hand, imparts hydrophilicity and provides a site for further chemical reactions, such as esterification or cross-linking.

Key Properties and Advantages of HEMA

HEMA’s widespread adoption stems from a unique combination of properties that offer significant advantages in various formulations:

- Excellent Polymerization Characteristics: HEMA readily polymerizes and copolymerizes with a wide range of other monomers. This allows for the tailoring of polymer properties to meet specific application needs.

- Dual Cure Reaction Capabilities: A significant attribute of HEMA is its compatibility with Dual Cure Reaction systems. This means it can be polymerized or cured using multiple mechanisms, often a combination of light (UV/EB) and heat or peroxide initiation. This provides greater processing flexibility and ensures thorough curing, even in shadowed areas of complex parts.

- Hydrophilicity: The presence of the hydroxyl group makes HEMA and its polymers relatively hydrophilic (water-loving). This is crucial for applications like soft contact lenses and hydrogels.

- Adhesion Promotion: HEMA can improve the adhesion of coatings and adhesives to various substrates due to its polarity and reactive hydroxyl group.

- Biocompatibility: Homopolymers of HEMA (poly-HEMA) exhibit excellent biocompatibility and minimal physiological rejection, making them highly suitable for medical polymers.

- Chemical Reactivity: The hydroxyl group can undergo further reactions, such as esterification, isocyanate reactions, or cross-linking, allowing for the creation of diverse polymer architectures and functionalities.

Diverse Applications: Where HEMA Makes a Difference

The versatile nature of Hydroxyethyl Methacrylate has led to its use in a multitude of applications, solidifying its status as a high-value specialty chemical.

Revolutionizing Medical Polymers

Perhaps one of the most impactful areas for HEMA is in the field of medical polymers. Its biocompatibility and ability to form hydrogels are paramount.

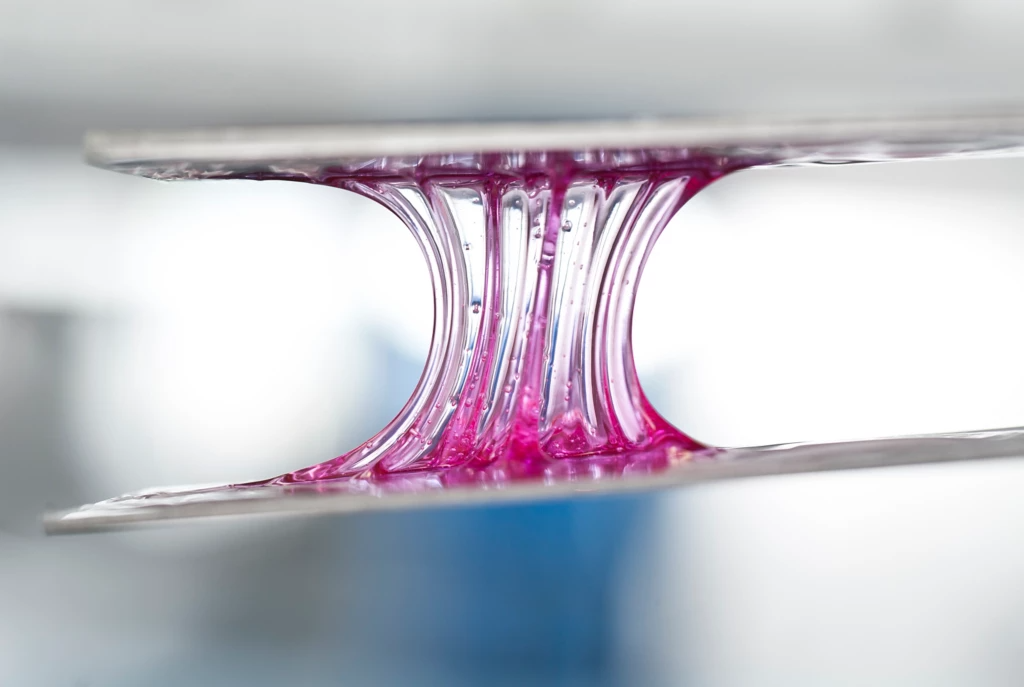

- Contact Lenses: HEMA was a groundbreaking monomer in the development of soft contact lenses. Poly-HEMA hydrogels can absorb significant amounts of water, leading to soft, flexible, and oxygen-permeable lenses. “Studies in ophthalmology materials show that HEMA-based hydrogels offer a balance of comfort, oxygen permeability, and durability, making them a mainstay for decades,” according to ophthalmic material reviews.

- Dental Materials: In dentistry, HEMA is a common component in dental composites, adhesives, and bonding agents. It enhances adhesion to tooth structures and improves the mechanical properties of restorations.

- Orthopedic Materials: HEMA finds use in bone cements and as a component in materials for cartilage repair or joint replacement technologies due to its biocompatibility.

- Drug Delivery Systems: The hydrophilic nature and biocompatibility of HEMA-based polymers make them suitable candidates for controlled drug release systems.

Illustrative Case Study: The Impact of HEMA on Soft Contact Lenses

Before HEMA, contact lenses were predominantly made from hard, impermeable plastics like PMMA. The introduction of HEMA in the 1960s revolutionized the industry. Its ability to form a soft, water-absorbent hydrogel led to the first commercially successful soft contact lenses. This dramatically improved wearer comfort and oxygen transmission to the cornea, making extended wear possible for millions. This innovation single-handedly expanded the contact lens market manifold.

Driving Innovation in Coatings, Resins, and Adhesives

HEMA’s reactivity and the properties it imparts to polymers are highly valued in the coatings, resins, and adhesives industries.

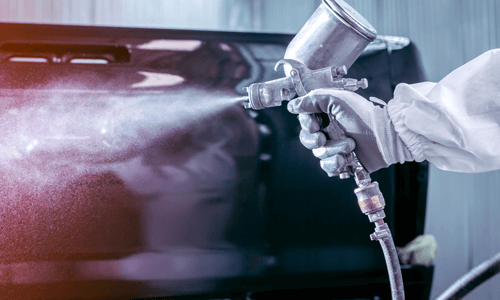

- Automotive Coatings: HEMA is used to synthesize acrylic resins containing active hydroxyl groups. These resins offer exceptional transparency, light transmission, and weather resistance, making them ideal for high-quality automotive coatings, particularly topcoats that require durability and aesthetic appeal. “Industry reports from 2023 indicate that the demand for durable and eco-friendlier automotive coatings is a key driver for HEMA consumption in this sector.”

- Light-Curing Resins (UV/EB Curable): As a reactive monomer, HEMA is a crucial ingredient in light-curing resins used in inks, coatings, and increasingly, in 3D printing (stereolithography). Its fast curing speed under UV or electron beam radiation improves production efficiency.

- Adhesives and Sealants: HEMA contributes to the performance of various adhesives, including anaerobic adhesives (where it can act as a stabilizer and reactive diluent) and structural adhesives. Its hydroxyl groups can enhance adhesion to polar substrates.

- Textile and Non-Woven Fabric Treatment: It is employed in binders for non-woven fabrics and for fiber treatment, improving the feel, durability, and other properties of textiles.

- Polymer Modification: HEMA can be grafted onto existing polymers or copolymerized to modify their properties, such as increasing hydrophilicity or providing reactive sites for cross-linking.

Illustrative Example: Enhancing Automotive Finishes

In modern automotive paint systems, HEMA-derived acrylic polyols are often reacted with isocyanates to form polyurethane coatings. These coatings provide the final “clear coat” layer on a car, offering high gloss, exceptional scratch resistance, and protection against UV degradation and chemical etch from environmental factors like acid rain or bird droppings. The hydroxyl functionality provided by HEMA is key to achieving the necessary cross-link density and performance.

The Global HEMA Market Landscape

HEMA is recognized globally as a specialty methacrylate ester with significant research investment, high market value, and strong demand. Due to its sophisticated production process, it’s considered a high-technical-barrier fine chemical product, leading to a relatively stable supply landscape. Major production hubs are concentrated in Europe, the Americas, and Asia.

Production Leaders and Trends

Historically, before 2020, high-purity, high-end HEMA production was predominantly concentrated in Japan, Germany, and the United States.

- Mitsubishi Chemical (Japan): This company has been a pioneer and remains one of the largest global HEMA producers, with a significant portion of its output exported, including to China.

- Evonik (Germany): Another major player, Evonik is known for its strong production capabilities and high-quality HEMA products that are competitive on the global stage.

“A 2024 market analysis suggests the global HEMA market is poised for steady growth, projected at a CAGR of 4-5% over the next five years, driven by its expanding applications in specialty coatings and medical devices.”

HEMA Production and Demand in China

In China, domestic HEMA production enterprises are generally smaller in scale compared to international giants. Key production activities are centered in provinces like Jiangsu, Shanghai, Anhui, and Shandong. Currently, these facilities primarily manufacture mid-to-low-end HEMA products, typically with purities around 95-96%. The supply of high-purity (97%+) HEMA, essential for demanding applications like advanced electronics or specific medical uses, remains limited from domestic sources.

However, the demand scenario in China is dynamic. The rapid expansion of the nation’s automotive industry, coupled with the fast-paced development of the downstream automotive coatings sector, has led to a significant surge in overall HEMA consumption. This growth is particularly pronounced for high-end HEMA products. This burgeoning demand presents both a challenge and an opportunity for domestic and international suppliers.

Ensuring Quality and Performance with HEMA

The purity and consistency of HEMA are critical for achieving desired end-product performance. Impurities can affect polymerization rates, polymer properties, and even the safety of medical devices. Therefore, sourcing high-quality HEMA from reliable manufacturers is crucial.

Considering its wide array of applications and the specific performance demands of each, how can you ensure HEMA is the right fit for your formulation? Understanding the grade, purity, and inhibitor package of the HEMA product is key.

Conclusion: The Enduring Importance of HEMA

Hydroxyethyl Methacrylate (HEMA) is far more than just another chemical intermediate. Its unique structural features, particularly the combination of a polymerizable methacrylate group and a reactive hydroxyl group, alongside its Dual Cure Reaction adaptability, have established it as a cornerstone Acrylate Monomer. From enhancing the comfort of contact lenses and the durability of automotive coatings to enabling advancements in light-curing resins and medical polymers, HEMA’s influence is extensive and growing.

Contact us today to discuss your requirements, request a sample, or receive a competitive quotation. Let us help you leverage the power of HEMA for your success!