1. Dual-Curable Aliphatic Polyurethane Polyurea Methacrylate Elastomer Resins

| Product | Key Features | Target Applications |

|---|---|---|

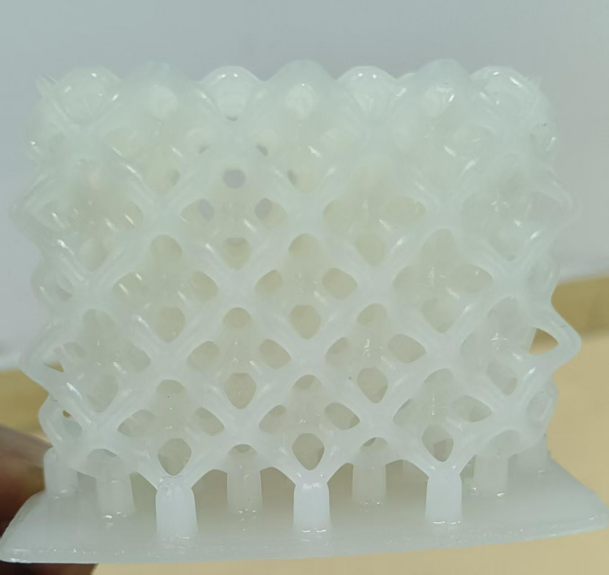

| UVU6203-3DF | High precision, low odor, excellent toughness, tear resistance, and UV/thermal dual curing. | Hollow shoe soles, elastic wearables, industrial prototypes. |

| UVU6203-3D | Low viscosity, fast curing, high elongation (400–800%), and superior adhesion to TPU. | DLP/LCD 3D printing for flexible models, ergonomic grips, and impact-resistant parts. |

| UVU6203-3DK1 | Skin-friendly, soft texture (Shore A 45–65), biocompatible, and high elasticity. | Medical devices, custom orthotics, consumer products requiring skin contact. |

2. Epoxy-Modified Cycloaliphatic Amine Curing Agent (UVU6203CA-3DE)

-

Function: Enhances mechanical properties, reduces odor, and improves thermal stability.

-

Applications:

-

Thermal curing agent for polyurethane resins.

-

Dual-curing systems for elastic 3D-printed parts.

-

Yellowing-resistant epoxy formulations.

-

Technical Specifications

Resins (A Component)

| Parameter | UVU6203-3DF | UVU6203-3D | UVU6203-3DK1 |

|---|---|---|---|

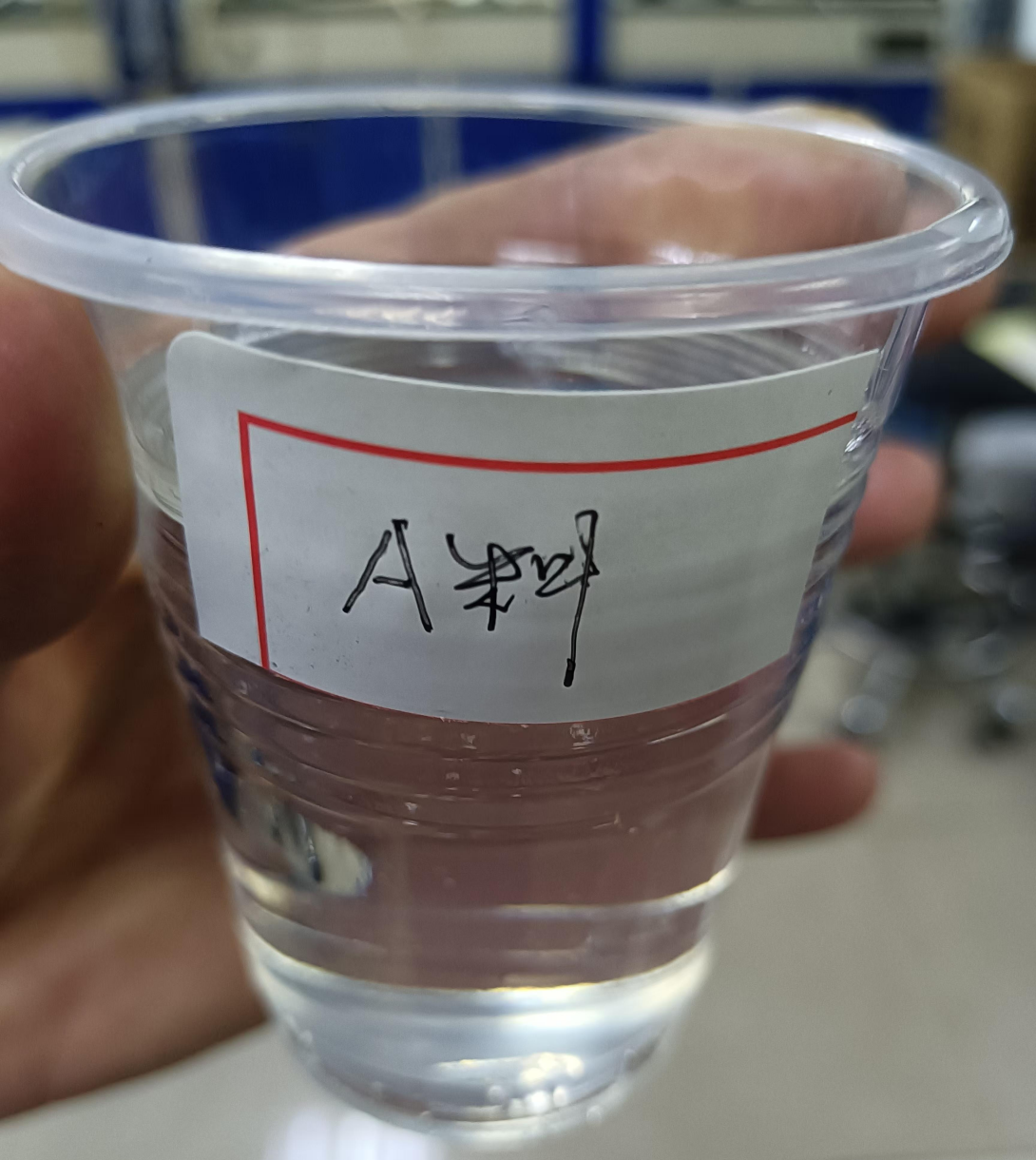

| Appearance | Pale yellow transparent | Pale yellow transparent | Milky white viscous |

| Viscosity (25°C) | 7,000–10,000 mPa·s | 2,500–3,500 mPa·s | 8,000–12,000 mPa·s |

| Elongation at Break | 400–800% | 400–800% | 350–700% |

| Tensile Strength | 10–30 MPa | 10–30 MPa | 10–20 MPa |

| Tear Resistance | 30–60 N | >60 N | >40 N |

| Shore Hardness (A) | 65–95 | 65–85 | 45–65 |

| Packaging | 20 kg / 200 kg drum | 20 kg / 200 kg drum | 20 kg / 200 kg drum |

Curing Agent (B Component: UVU6203CA-3DE)

| Parameter | Specification |

|---|---|

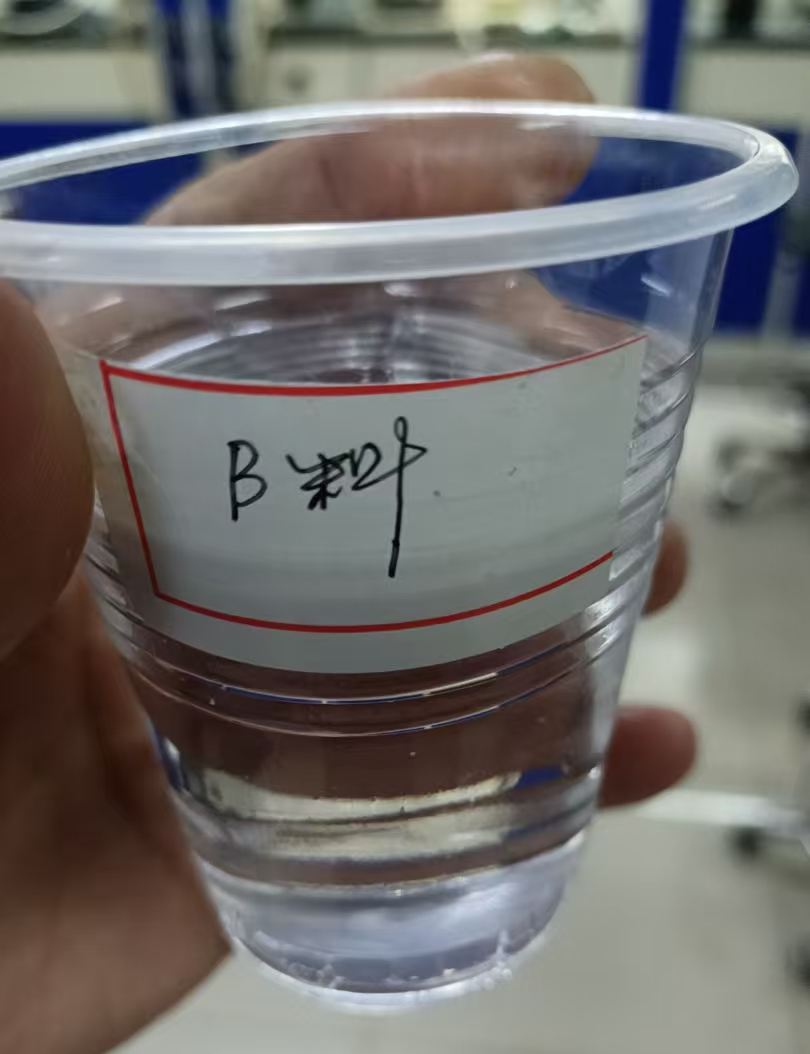

| Appearance | Pale yellow viscous liquid |

| Viscosity (25°C) | 3,500–6,000 mPa·s |

| Amine Value | 280–350 mg KOH/g |

| Odor | Slight ammonia smell |

| Packaging | 20 kg / 200 kg drum |

Key Advantages

-

Fast Curing: UV/thermal dual-curing for rapid prototyping (4–9 seconds exposure time).

-

High Precision: Compatible with DLP/LCD printers (25–40°C printing temperature).

-

Eco-Friendly: NCO-free, organotin-free, and low VOC emissions.

-

Durability: Excellent thermal stability (-20°C to 100°C) and UV resistance.

Application Guidelines

-

Mixing Ratio:

-

UVU6203-3DF/3D: 93–96% Resin A + 4–10% Curing Agent B + 1.5–2% photoinitiator.

-

UVU6203-3DK1: 100:10 (Resin A:B) + 1.5–2% photoinitiator.

-

-

Post-Processing:

-

Wash printed parts and cure at 90–110°C for 1–2 hours.

-

-

Recommended Use:

-

Footwear: Hollow soles, insoles.

-

Medical: Skin-contact devices, orthotics.

-

Industrial: Flexible joints, seals.

-

Packaging & Storage:

-

20 kg / 200 kg drums.

-

Store in a cool, dry place (<30°C). Shelf life: 12 months.

Contact Us:

For samples, technical support, or custom formulations, visit www.sinocurechem.com or email info@sinocurechem.com.

Discover Innovation at Our Exhibitions:

-

CHINACOAT 2025 (Booth E4B01, Shanghai, Nov 25–27)

-

DyeChem Bangladesh 2025 (Booth BA24, Dhaka, Sep 10–13)

This comprehensive product line combines precision, durability, and versatility for next-generation 3D printing solutions. Let’s shape the future together!