SINOMER UVU6203-3DF

Product Name: Dual-Cure Aliphatic Polyurethane Polyurea Methacrylate Elastomer Resin

Application: DLP 3D Printing

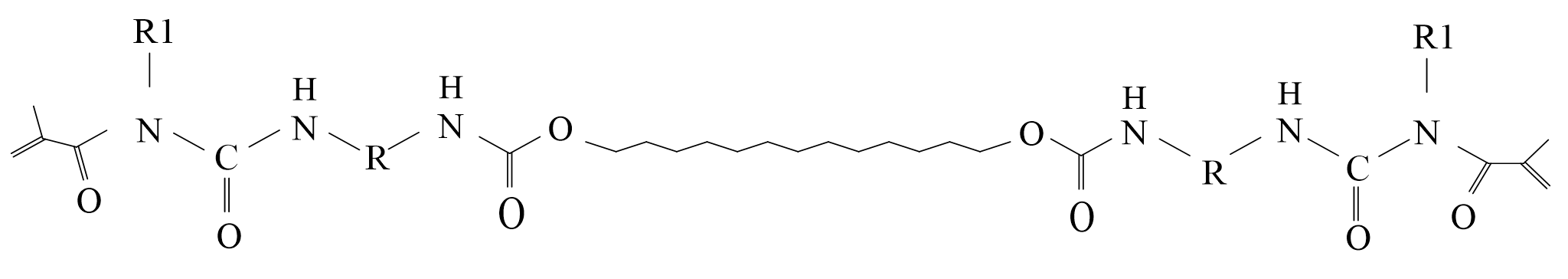

Chemical structure:

Product Overview

UVU6203-3DF is a two-component (A/B) dual-cure aliphatic polyurethane polyurea methacrylate elastomer resin designed for DLP 3D printing. It features high precision, moderate viscosity, no NCOₓ or organotin, low odor, light color, excellent toughness, high tensile strength, tear resistance, flexibility, elongation at break, elasticity, photosensitivity, and wear resistance.

Physical Properties

| Property | Value |

|---|---|

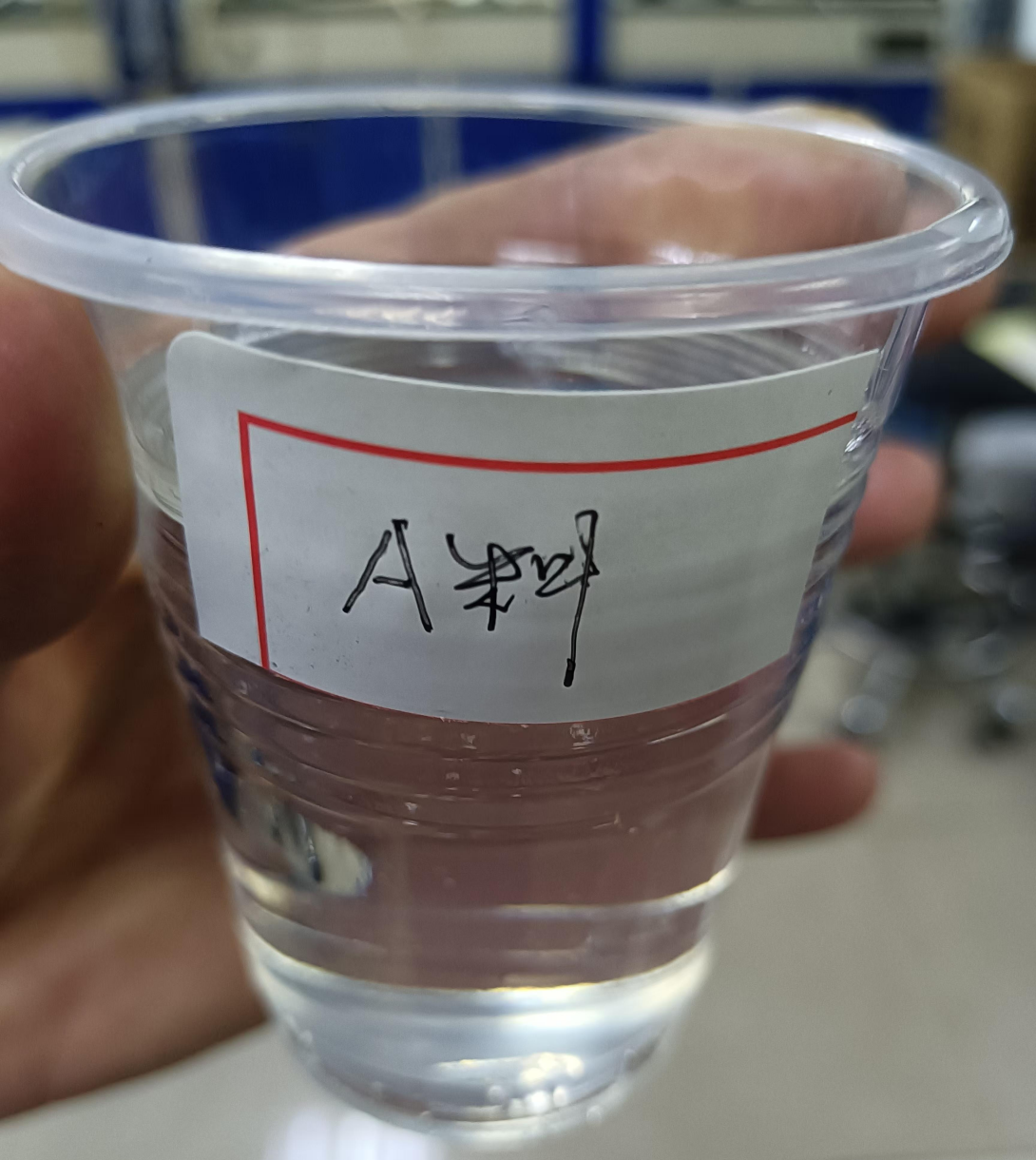

| Appearance | Slightly yellow, transparent viscous liquid |

| Color (Pt-Co) | ≤40# |

| Viscosity (25°C, mPa·s) | 7,000–10,000 |

| NCO Content | 0% |

| Elongation at Break (%) | 400–800 |

| Tensile Strength (MPa) | 10–30 |

| Tear Strength (N) | 30–60 |

| Shore Hardness (A) | 65–95 |

| Packaging (kg/drum) | 20/200 |

Key Features

-

Fast curing speed

-

Light color

-

Low odor

-

High printing precision

-

Excellent adhesion on TPU

-

Superior toughness and flexibility

-

High tensile strength and elongation

-

Tear resistance

-

Anti-yellowing

Applications

-

Mixing Ratio: A: 93–96% + B(UVU6203-3DK1 curing agent): 6–10% + 1.5–2% photoinitiator.

-

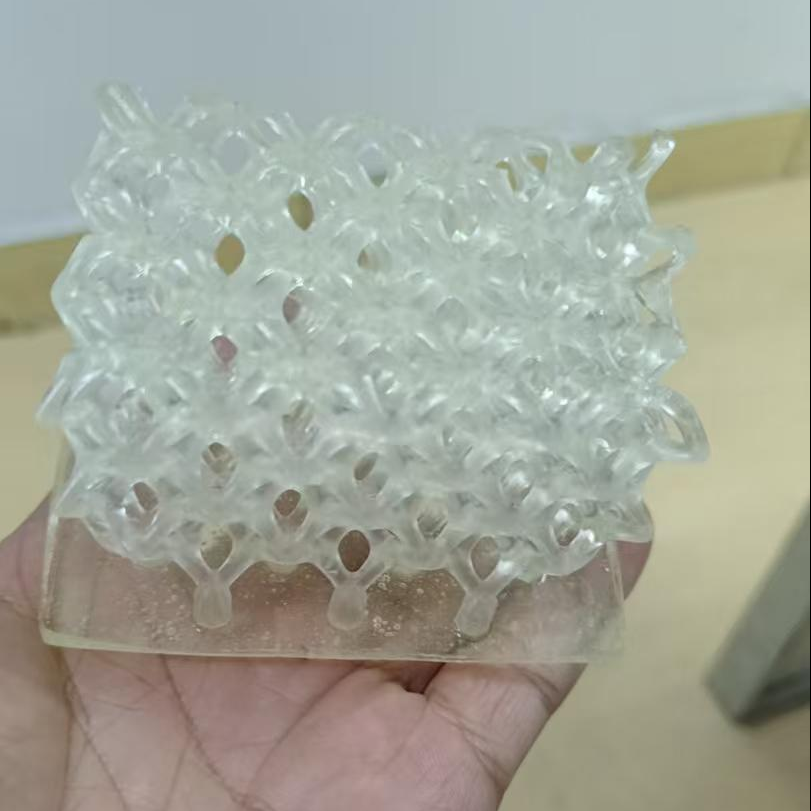

Application 1: Ideal for photopolymerized 3D hollow models, hollow soles, and flexible/wear-resistant elastic parts.

-

Printing Parameters:

-

Temperature: 25–40°C

-

Exposure Time: 4–8 seconds

-

Post-Curing: Bake at 90–110°C for 1–2 hours.

-

-

Usage Range: -10°C to 100°C.

-

-

Application 2: Surface coating for TPU elastomers (thermal or dual-cure).

Storage:

Being kept in dry, clean warehouse with well ventilation. Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

The shelf life of SINOMER UVU6203-3DF is 12 months under proper storage.

Details

| Product description: | DLP 3D Printing Dual-Cure Aliphatic Polyurethane Polyurea Methacrylate Elastomer Resin |

|---|---|

| Viscosity (cps@25°C) | 7,000–10,000 |

| Elongation at Break (%) | 400–800 |

| Tensile Strength (MPa) | 10–30 |

| Tear Strength (N) | 30~60 |

| Shore Hardness (A) | 65–95 |

Reviews

There are no reviews yet.